Hey everyone,

Welcome to our brand-new content (for the foreseeable future) where we’re pulling back the curtain on our latest development projects!

A lot is happening behind the scenes, and we’re thrilled to finally share the journey with you.

You might be wondering about the rest of our Quality Management checklist library. Don't worry—we're still committed to completing them! The final ones, like our Painting Quality Checklist, are in process now and the last few have been drafted pending data input and formatting (time consuming stuff).

First Up: A Look at Our Two New Projects

For the past 11 months, we’ve been laying the groundwork for not one, but two exciting new developments. We're just waiting on Development Approval (DA) to get the official green light before this projec kicks off (and early works Building Approval (BA) can be issued).

This first post in is all about Project #1

It's a residential house (a Class 1A building) that we're constructing to commercial-grade standards. (Project #2 is a Class 2 building, and we’ll dive into that later).

Our goal with this series is simple: to show you the "what," "how," and "why" of what we do. We'll walk you through our processes up close and explain the reasoning behind every material we choose and every method we use.

Project Overview: From the Ground Up

So, what exactly is Project #1? For the last 11 months, our focus has been on the foundational work: project management, contract administration, and meticulous planning.

On this project, we wear two key hats.

The first hat is as the Client-Side Project Manager and Developer. In this role, we orchestrate everything required to turn the initial idea into an approved, ready-to-build reality.

The second hat is as the Construction Manager and Builder. Once enough of the the plans are set, DA and BA is issued, we switch gears to organise and execute the physical construction, bringing the plans to life.

The general project scope involves demolishing the existing structure to make way for a modern new build. The new design features a basement level plus three stories above ground.

Since November 2024, we've been deep in the preliminary design phase with our full team of consultants—the architect, structural engineer, civil engineer, and more.

After countless meetings and discussions, we're finally nearing the "pointy end" of the project, where we start the physical work on site.

Showing, Not Just Telling

We believe the best way to share this process is to show you each step as it happens. So, we're taking you on the journey with us!

We've even geared up with lavalier mics and receivers and have started filming on-site to bring you along for the ride. The format will be simple: we'll walk the site and talk you through what's happening, explaining the discussions and decisions that drive our work, from material selection to construction methods.

I also want to be upfront about our approach. Like all builders, we have our own preferences and biases based on past experiences. The way we build is our way, but it's certainly not the only way. This project will be built according to the design created by our consultants, in conjunction with our input and, most importantly, the client's vision.

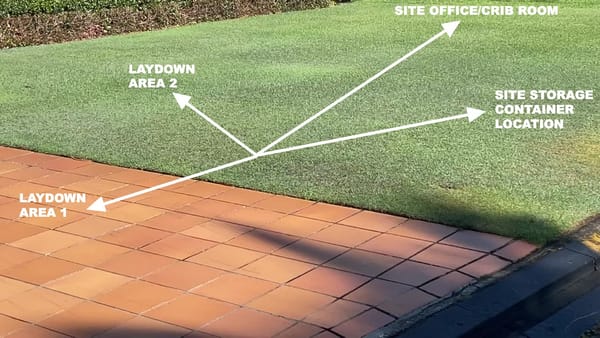

Site Overview: Laying the Groundwork

This week, we began preparing the site. You might spot blue markings on the ground—these are important. They indicate the location and depth of essential services like water and power, which range from 750mm to 1.3m deep.

This detailed planning is a perfect example of the essential preliminary work that happens long before the demolition crew arrives. It’s all about ensuring safety and efficiency from day one.

What's Next: Demolition and Early Works

The next major milestone is the demolition of the existing dwelling and all other structures on the site to make way for the new construction.

We've already engaged a demolition contractor and are in the final stages of locking in a date, which we expect to be in early January 2026.

After that, the real transformation begins. The schedule includes:

- Sheet Piling & Dewatering: Stabilizing the site for a deep dig.

- Bulk Excavation: Removing approximately 2000m³ of earth to create the basement.

- Basement Construction: Pouring the foundation for the new structure.

An Australian-First Innovation

We're also testing something new and exciting: a pioneering polymer in the sheet piling process. It's the first project in Australia to use it! I've affectionately nicknamed it "KY for sheet piling."

While that name is a simple analogy, its function is much more complex than just being a lubricant. If this trial is successful, it could fundamentally change the types of projects where sheet piling is a viable option. We're collaborating closely with the sheet piling contractor and the geotechnical engineer to make it work. It’s a fascinating experiment, and we're keeping our fingers crossed for a positive outcome.

A Long-Term Project, A Transparent Journey

Stay tuned for more updates as we move from the drawing board to the construction site. This is a significant build—a large house that we anticipate will take approximately 2 to 2.5 years to complete.

We're genuinely excited to share this entire journey with you, offering a deeper look into what goes into a high-spec house construction. This project is particularly interesting for several reasons: the advanced construction methods, the detail of inclusions, and the very high level of finish and fittings required.

Thanks for following along. We hope you enjoy this series as much as we enjoy bringing it to you!

Regards,

Anthony

Member discussion