Ever wondered what that black layer is that you see in the walls of buildings? Chances are it's a damp proof course or DPC. As a homeowner, DPCs are one of those things you don't give much thought to until there's a problem with damp in your house. But DPCs play an important role in keeping your home dry and preventing damage.

DPCs are typically made of materials like polyethylene, bitumen or metal that water can't pass through. They're installed in a layer of the wall that's below ground level, usually just above the foundations. The DPC creates a barrier between the parts of the wall in contact with the ground and the higher wall sections and floors to stop dampness and water damage in the home.

A damp proof course or DPC is a protective barrier installed in walls and floors to prevent moisture damage. Its job is to stop dampness rising up from the ground into the structure of your home.

You'll typically find a DPC layer in the foundations, about 15cm (150mm or approximately two bricks) above ground level. It's made of waterproof material, like bitumen, polyethylene sheeting or mortar additives. The DPC creates an impermeable barrier, blocking water molecules and water vapour from seeping into the building materials above.

DPC or Cavity Flashing?

DPC flashing is covered in some detail—though not with absolute clarity—in AS4773.2 Masonry for Small Buildings.

The standard mainly states that the flashing must be continuous or have minimum laps to maintain integrity.Another key point is that a flashing that extends through the masonry is considered a DPC (as in a cavity flashing).

So, in the case of a step, it’s possible to use compliant material (refer to Table 5.2) for the flashing step (if its a big step) along with a separate DPC lapped to meet the requirements.

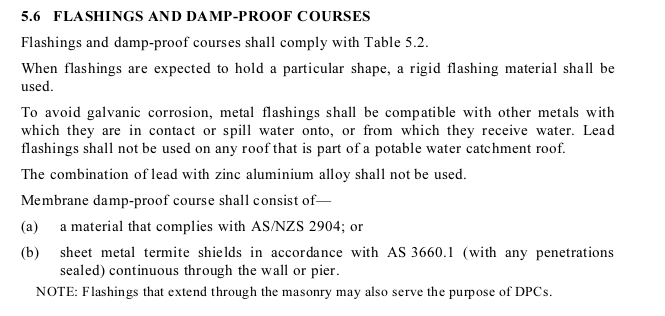

The main consideration around the type of material(s) to use will depend on the exposure classification for the house (proximity to breaking water) or DPC location (per table 5.2 below).

Of course ensuring to avoid dis-similar metals if a metal flashing(s) is used. Interestingly, some termite barriers also work as DPC's when they meet the requirements. The Termite companies will point this out in their specification when it applies as a selling point (why their system is awesome).

Page 22 of 4773.2:

Page 23 of 4773.2:

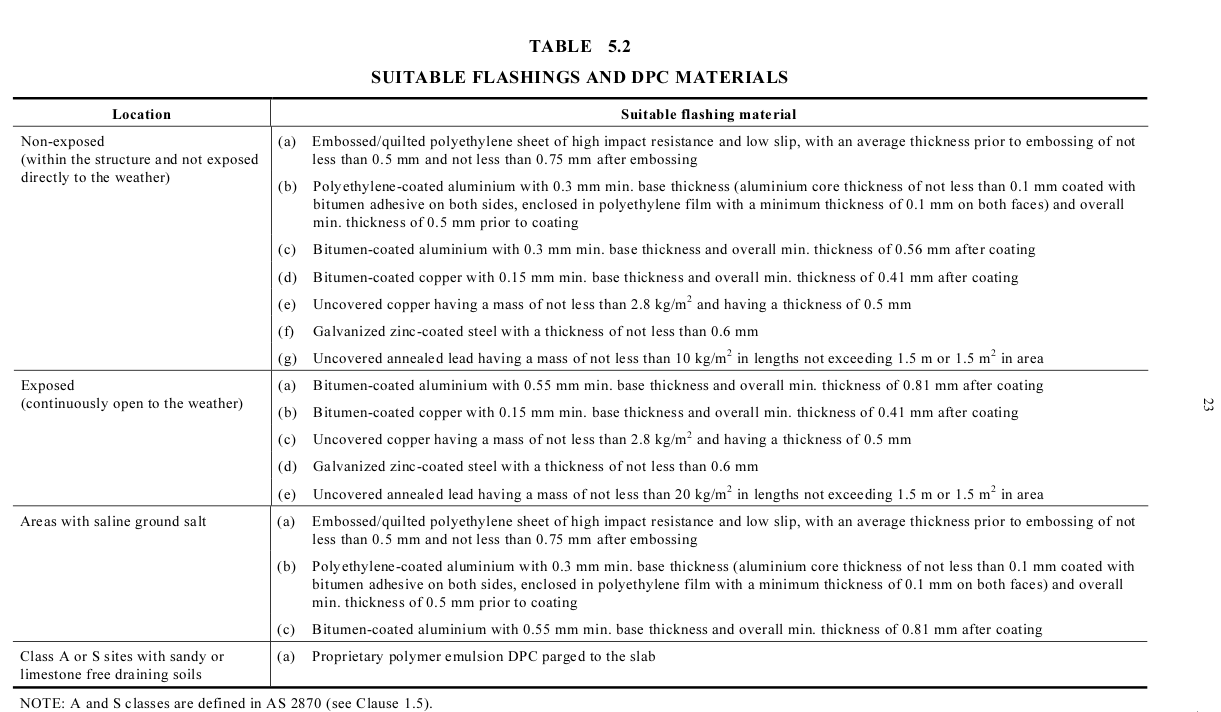

Page 49 Clause 9.6 of 4773.2:

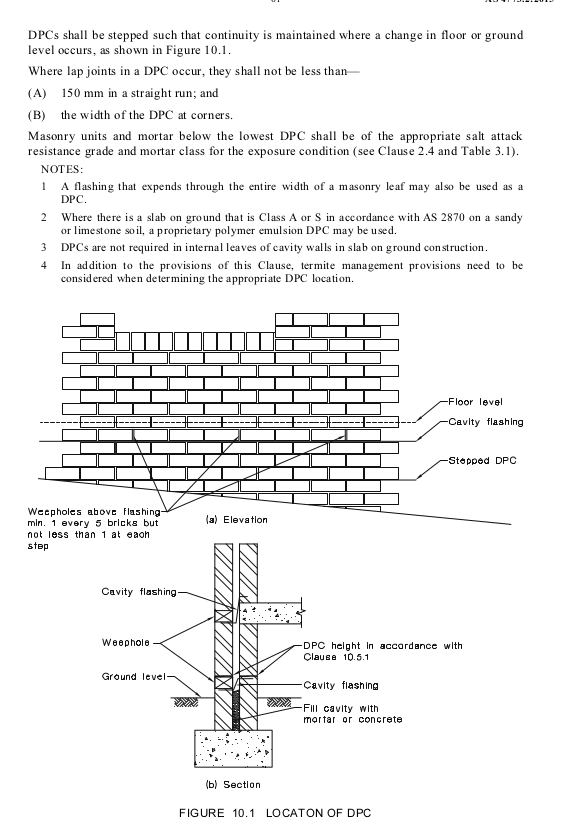

"DPCs shall be stepped such that continuity is maintained where a change in floor or ground level occurs." Notes (on Page 49) also say - "A flashing that extends through the entire width of a masonry leaf may also be used as a DPC."

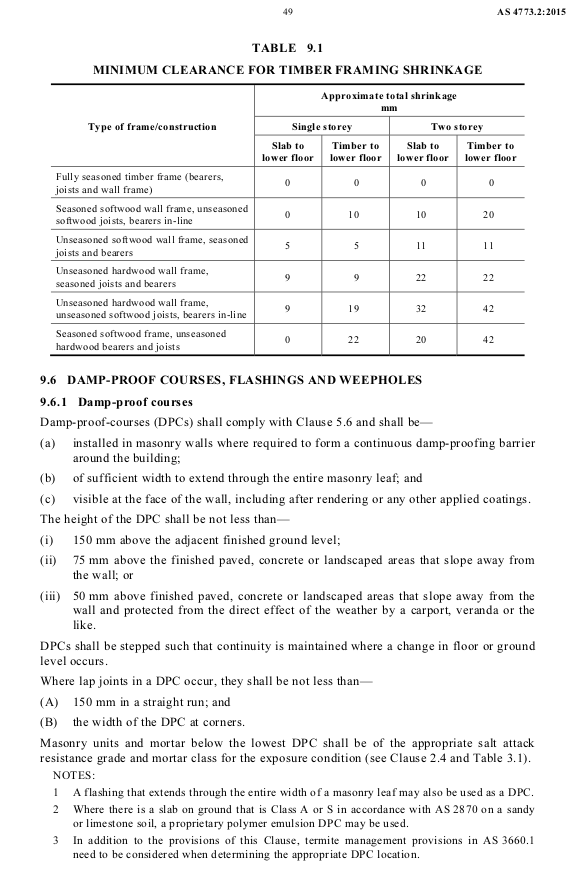

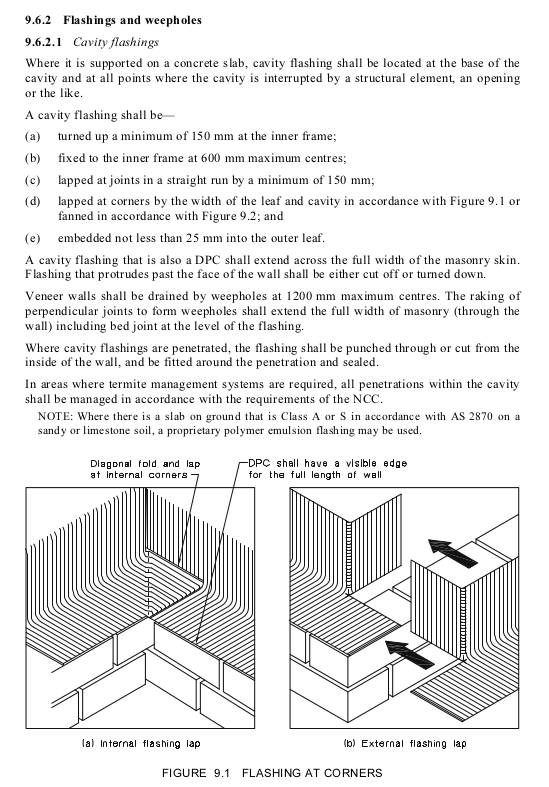

Page 50 of 4773.2:

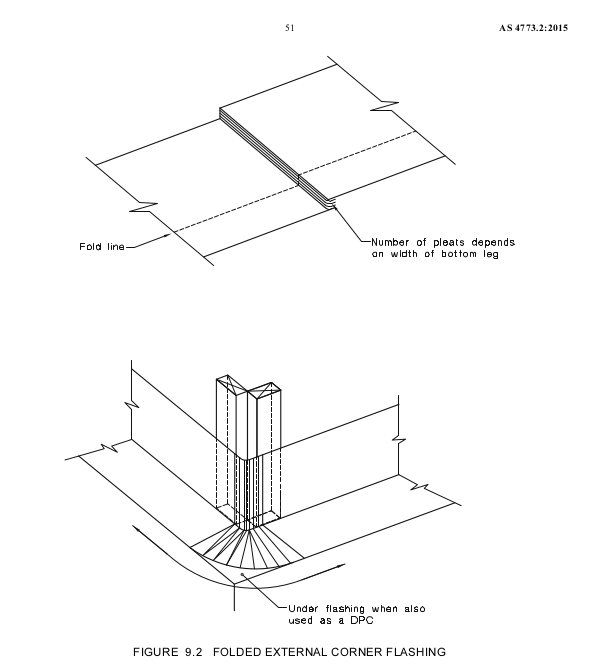

And Page 51 of AS4773.2:

And lastly Page 61 talks about "DPCs shall be stepped such that continuity is maintained where a change in floor or ground level occurs, as shown in Figure 10.1." The main takeaway is having continuity and minimum laps (150mm) maintained

Stepped DPCs

AS3700 Masonry Structures talks about DPCs as well but not in the detail of 4773.2, more just says "you need to have one to prevent moisture."

👉️ DPC – A (DPC) acts as a continuous horizontal barrier, preventing moisture from rising up through walls via capillary action (rising damp). It’s usually installed just above the first course of bricks, typically about 86mm above adjacent ground levels.

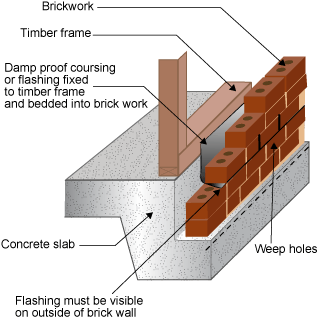

In typical brick veneer (brick external skin + frame internal wall) residential house construction, the DPC is often 300mm-wide polyethylene, lapping the brick width and fixed to the wall frame with the wall wrap lapping over it (by 150mm) once installed.

Example of a DPC

A wide cavity flashing can serve as a DPC if it extends from the inner wall face to the outer brickwork, draining moisture through the weep holes (as shown in the images below).

👉️ Cavity Flashing – Cavity flashing captures and redirects water that enters the cavity, usually from wind-driven rain or leaks, back to the exterior through weep holes. It’s typically installed at window heads, sills, or base courses.

A Typical Cavity Flashing Detail

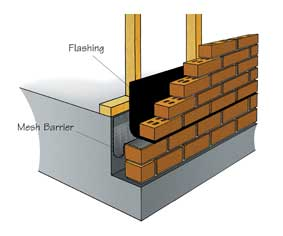

Termite Barrier – If the termite barrier isn’t a DPC, YES, you’ll need both a termite barrier and a DPC. Many builders combine the DPC with the cavity flashing in a brick veneer facade, as shown in the attached detail below, so it serves both functions.Some termite systems like Termi Mesh require the first course of brickwork to be down before the mesh barrier is parged/stuck to the slab edge rebate then over the top of the 1st course of bricks.

Other termite barriers like Kordon or chemical impregnated style barriers are fixed to the top of the slab before the wall frames are stood on top of, then brought through the cavity, over the first course of bricks.

In the case of Termi Mesh, the Cavity flashing/DPC goes over the top of the mesh barrier extended to the outer face of the wall skin (see image below).

Physical Termite Barrier And Brick Veneer

In short, a DPC stops rising damp and is usually just masonry-wide, while a cavity flashing drains moisture from inside the cavity to the outside.

Below are some window installation manuals that have details showing cavity flashings (head and sill flashings) around window and door openings.

Installation manuals showing window flashing which acts as a form of cavity flashing around the opening in the facade

The Head and Sill flashings (collects jamb flashing) and drains to weepholes in the facade.

So, in summary, A DPC typically is only masonry unit wide and stops rising damp, where as a cavity flashing drains/directs water from the inside of the cavity to the outside through weepholes.

👉️ When a cavity flashing is a DPC as is often the case in residential house construction, its very important that the cavity is clean and not "full of mortar dags". The cavity is supposed to be a consistent width, no less than 40mm and formed to ensure moisture can drain down the cavity to the flashing where it exists through the weepholes.

In effect its a drain and ventilation system for the area between the back of the brick wall and the face of your internal wall and frame.

Further Reading

Member discussion