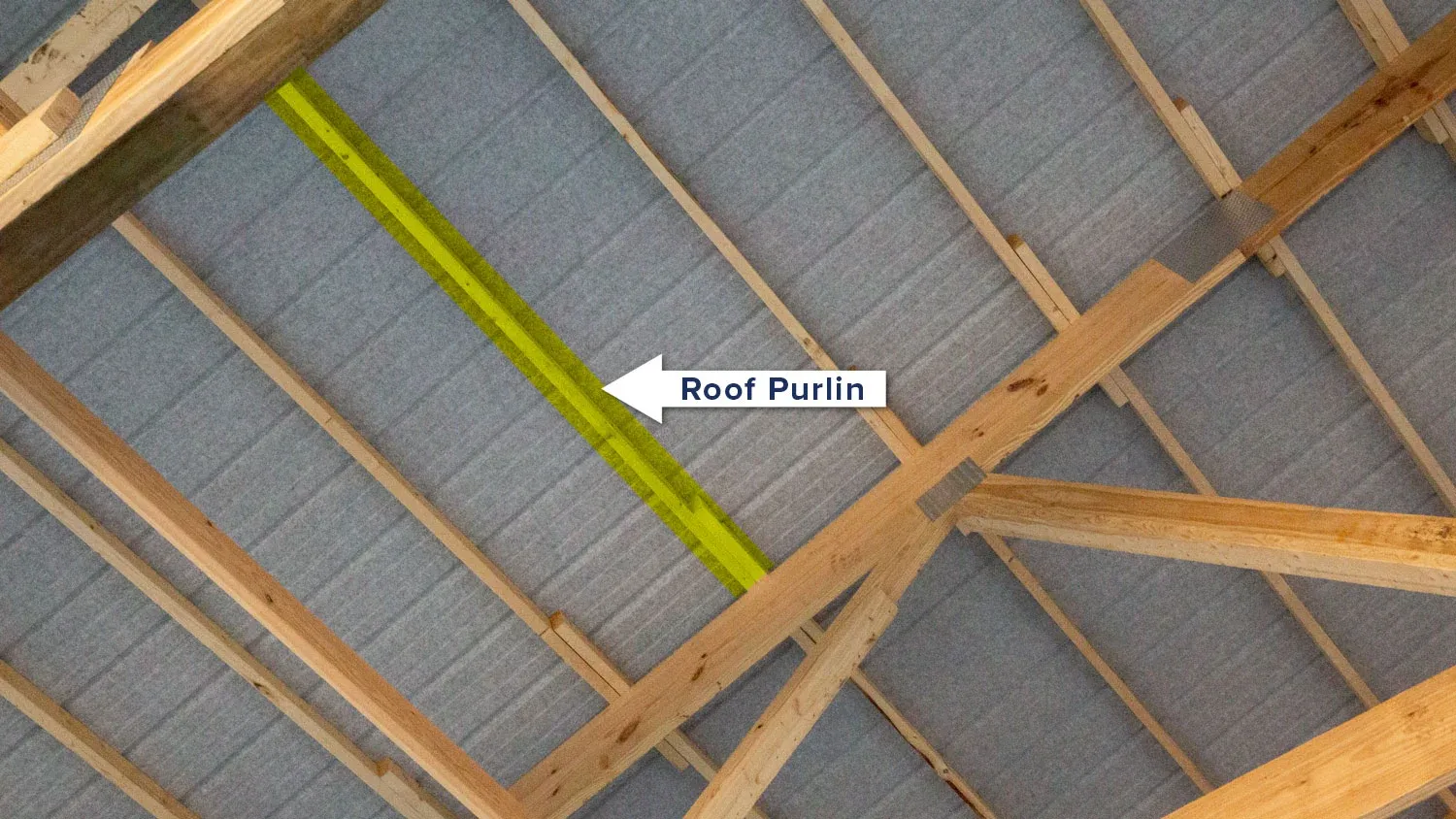

🏠 What is a Roof Purlin?

A roof purlin is a key horizontal structural member used in construction to support the roof decking or roofing materials of a building. These beams run across the length or width of the roof, resting on the primary framing system—which includes larger structural elements like steel beams or walls of the building.

The purlins help to distribute the weight of the roof deck, ensuring the load is evenly shared and reducing the risk of roof failure.

There are several types of purlins used in the construction industry, each designed to meet different project needs:

- C Purlins: These have a c-shaped cross-section and are commonly used in metal buildings and steel structures. C-shaped purlins are great for projects where you need a strong, versatile beam that’s easy to install.

- Z Purlins: Shaped like a Z, these purlins offer more structural strength and can span longer spans compared to C purlins. Their overlapping design allows for lap length connections, making them ideal for large industrial buildings or chemical plants.

- U Sections and U Shapes: Sometimes referred to as channel sections, these are used for certain applications where a different profile is needed.

- Timber Purlins: While steel purlins dominate modern construction, timber purlins are still found in timber frame structures and older homes, providing an alternative to metal purlins in smaller projects.

Purlins are often made from hot-rolled steel, cold-formed steel c, or even red oxide purlins (which are coated with a red primer to resist corrosion). Hot-formed steel and advanced technology manufacturing allow for various sizes, shapes, and finishes, ensuring purlins meet the structural needs of different projects.

In practical terms, think of roof purlins as the support structures that hold everything together:

When Do You Need Roof Purlins?

You’ll need roof purlins whenever a roof structure requires horizontal support between the primary framing system and the roofing materials.

- Residential Construction: In timber frame structures or homes with metal roofs, purlins are required for holding up the roofing sheets. For example, a custom home with longer spans in areas like a great room or open-plan living space often needs horizontal beams such as c purlins or z purlins to bridge those wide gaps. This avoids sagging and maintains the structural integrity of the roof.

- Steel Structures and Metal Buildings: In commercial and industrial structures—like metal buildings, warehouses, and industrial buildings—you’ll find steel purlins used extensively. Their structural strength allows them to span wide areas with minimal support from underneath. Z-shaped purlins and c-shaped purlins provide excellent load-bearing capacity, especially in buildings with metal sheeting or thin sheets of steel. These purlins are often used alongside eave struts, wall joists, and parapet rails to complete the secondary framing components of the structure.

- Agricultural Buildings and Sheds: For structures like barns, metal roof carports, and farm sheds, purlins support the weight of roofing sheets, help distribute loads, and make room for insulation material. They’re often paired with flange stiffeners, lap length connections, and other structural elements to reinforce the overall framework.

- Commercial Construction Projects: Office buildings, shopping centres, and buildings with large roofs depend on purlins to connect to the primary framing system, providing a stable base for roofing materials like steel sheets or metal panels. These purlins might be made from hot-rolled steel, hot-formed steel, or cold-formed steel c sections for added durability and resistance to environmental factors.

- Retrofits and Extensions: Even when adding on to an existing structure—say a sun room or covered patio—purlin spans are often necessary to support new roofing. Here, timber purlins might still be used, especially when matching existing timber panels or designs.

In all these cases, the choice of type of purlin—whether c purlins, z purlins, or timber purlins—depends on the project’s requirements:

--the spacing of purlins, the weight of the roof deck, the desired shape, and even factors like exposure to weather (site exposure classification)(where a layer of paint or red primer like that used in red oxide purlins might be specified).

🪚 What’s Included in a Roof Purlin Project?

When you hear the term roof purlin project, it might sound like a big, complicated task. But when we break it down, it’s all about selecting the right type of purlins and installing them properly to support the roof.

Here’s what’s typically involved in a roof purlin project—from design to installation:

1. Design and Planning

Everything starts with structural engineering. Engineers and designers evaluate the construction project to determine how the roof should be supported. This includes:

- Calculating the load-bearing capacity: How much weight will the purlins need to support? This includes the weight of the roof deck, roofing materials like metal sheeting or steel sheets, and even environmental factors like snow or wind.

- Deciding on the spacing of purlins: This refers to how far apart the purlins are placed. Wider purlin spans might be used in large industrial buildings or metal buildings, while tighter spacing could be necessary for timber-frame structures.

- Choosing the right type of purlin: Will the project use c purlins, z purlins, or even timber purlins? The choice depends on the structural strength needed, the desired shape, and the overall design of the roof.

2. Material Selection

The next step is selecting the best material for the job. This decision often comes down to balancing cost, durability, and suitability for the project:

- Steel purlins like c-shaped purlins, z-shaped purlins, or z shapes are common in modern buildings. These can be made from hot-rolled steel, cold-formed steel c, or hot-formed steel, ensuring structural integrity and resistance to environmental factors.

- Timber purlins might still be used in smaller residential projects or for aesthetic reasons in timber panels.

- In harsher environments, purlins might be coated with a layer of paint, red primer, or manufactured as red oxide purlins to resist corrosion.

- Special components like flange stiffeners, eave struts, channel sections, single cleats, and support structures are chosen based on the roof’s design needs.

3. Fabrication and Delivery

Once the materials are selected, the purlins are fabricated:

- C purlin roll processes are used to shape thin sheets of steel into the desired profiles for metal roof systems.

- Manufacturers produce various sizes of purlins to match the building’s design, including single spans, u sections, and even structural shapes that accommodate different purlins.

- After fabrication, the materials are transported to the site, ready for installation.

4. Installation

The installation phase is where the purlins are placed and secured:

- Purlins are attached to the primary framing system, such as steel beams, building walls, or wall joists, using single cleats, bolts, or welding where needed.

- Installers check that each purlin is aligned correctly, ensuring that roofing sheets, metal roof panels, or timber panels will sit evenly on top.

- In large construction projects, additional support structures like eave purlins, parapet rails, and door mounting or window trimming elements might be incorporated.

- Proper spacing is key—this determines how the roof decking is supported and prevents sagging over time.

5. Quality Checks and Adjustments

Before calling it a day, the team checks everything:

- Ensuring purlins are correctly installed and spaced, with attention to purlin span and alignment.

- Verifying that components like flange stiffeners, u shapes, and channel sections meet specifications.

- Applying protective coatings where needed, such as a red primer or paint, to ensure long-term durability.

A roof purlin project might also involve coordinating with suppliers for a free quote, especially for larger steel construction jobs.

📐Who Designs and Installs Roof Purlins?

When you’re building a home or a larger construction project, you might wonder: Who’s responsible for making sure those roof purlins are designed correctly and installed securely?

The answer involves a few key players in the construction industry:

1. Structural Engineers

The initial design of the roof purlins is typically handled by structural engineering professionals. Their job is to calculate the load-bearing capacity of the roof and determine:

- The type of purlin best suited for the project (whether c purlins, z purlins, timber purlins, or steel purlins).

- The spacing of purlins based on the building’s size and the weight of the roof deck.

- The right materials, which might include hot-rolled steel, cold-formed steel c, or timber panels.

- Considerations for flange stiffeners, lap length, and purlin span to ensure the structure remains safe and durable.

They use advanced technology and representative designations to create precise plans for how the horizontal beams (purlins) should be integrated into the primary framing system of the building.

2. Builders and Contractors

Once the design is finalised, builders and contractors take over. They’re responsible for:

- Ordering the materials, which could include red oxide purlins, metal purlins, or timber purlins, depending on the design.

- Coordinating with suppliers and fabricators to ensure delivery of the correct structural elements like c-shaped purlins, z-shaped purlins, or u sections.

- Installing the purlins by securing them to steel beams, wall joists, or other support structures using single cleats, bolts, or welding.

- Ensuring everything lines up perfectly for the roofing sheets, metal sheeting, or timber panels to be installed securely.

3. Fabricators and Manufacturers

These teams create the physical purlins. Using c purlin roll processes, hot-formed steel, or cold-formed steel, they produce the purlins to the project’s specifications. They often apply protective coatings such as a layer of paint or red primer to prevent rust and ensure long-lasting performance, especially in areas exposed to moisture.

4. Quality Inspectors

Before signing off, quality control inspectors or site supervisors check the installation:

- Verifying that purlins are correctly spaced, aligned, and secured.

- Ensuring purlin span meets design requirements.

- Checking for the correct use of flange stiffeners, eave struts, and other support structures.

5. Homeowners and Clients

While not directly involved in design or installation, homeowners and clients should be informed participants. Asking for a free quote, reviewing design plans, and ensuring that purlins meet standards for structural integrity and roofing material compatibility can save headaches later.

⚠️ Why Should You Use Roof Purlins?

If you’re planning a new build or renovation, you might wonder, “Do I really need roof purlins?” The answer is almost always yes—

Especially if you’re aiming for a safe, sturdy, and long-lasting roof. Let’s explore why roof purlins are essential, and how they help improve the structural integrity of your home or building.

1. Essential Structural Support

At their core, purlins are horizontal structural members that provide the framework for your roof. Without them, the roofing materials like metal sheeting, roofing sheets, or timber panels wouldn’t have the support they need. Imagine trying to build a roof without these beams—you’d likely see sagging, shifting, or worse.

Purlins help to evenly distribute the weight of the roof deck across the primary framing system, which might include steel beams, building walls, or even timber frame structures. By doing this, they prevent localised stress points that could lead to cracks or structural failure over time.

2. Longer Spans and Greater Flexibility

Modern buildings—whether they’re metal buildings, industrial buildings, or even residential homes with open great rooms—often need longer spans to create uninterrupted spaces. Z purlins, with their unique z shapes, are particularly useful for this purpose, offering enhanced structural strength and load-bearing capacity. They can overlap at joints (known as lap length) to create continuous runs that cover wide roofs.

Similarly, c purlins or c-shaped purlins provide reliable support for roofs of various sizes, making them suitable for a wide range of construction projects—from small sheds to large steel structures.

3. Compatibility with Various Roofing Materials

Whether you’re using metal roof systems, thin sheets of steel, timber panels, or insulation material, purlins adapt to your material choices. They create a solid base for sheet support, allowing for the easy installation of roofing sheets, and they help anchor roof decking securely.

In fact, purlins are often custom-fabricated in various sizes, structural shapes, and coatings like red primer or layer of paint (as seen in red oxide purlins) to meet specific material requirements.

4. Efficiency and Cost-Effectiveness

Using purlins can actually save you money in the long run. How?

- Steel purlins such as hot-rolled steel or cold-formed steel c are designed to be lightweight yet strong, reducing the need for heavy, costly framing materials.

- The use of advanced technology in fabrication ensures precision and consistency, cutting down on waste and installation errors.

- Properly installed purlins, spaced according to the building’s needs, reduce the risk of future repairs by maintaining the structural support of the roof.

5. Design Versatility

With different types of purlins available—like z-shaped purlins, c purlins, and even timber purlins—builders and designers have the flexibility to choose the right option for each project. Whether you need channel sections, u shapes, or u sections, there’s a purlin for every design vision.

6. Enhanced Durability

Many purlins, especially in metal buildings or steel construction, are treated with protective coatings (like red primer) to resist corrosion. This ensures they can withstand harsh environments—whether it’s moisture in chemical plants, exposure to extreme weather in industrial buildings, or even the salty air near coastal homes.

7. Support for Complex Designs

Complex roof structures, such as those with multiple levels, eave struts, parapet rails, or different purlins at varying heights, depend on the adaptability of purlins. They make it possible to support innovative roof designs, including features like door mounting systems or window trimming.

8. Future-Proof Your Building

By incorporating purlins designed for your building’s unique needs, you’re not just meeting today’s standards—you’re preparing for the future. The inclusion of purlins of a roof support system makes it easier to upgrade roofing materials, add insulation, or adjust structural elements down the line.

9. Widespread Industry Use

From buildings to large-scale commercial complexes and residential homes, the use of purlins is a standard practice in the construction industry. Their role as secondary framing components connects them directly to the primary framing system, ensuring everything holds together as designed.

🎯 Challenges and Best Practices of Introducing Roof Purlins

While roof purlins are an essential component in many construction projects, incorporating them isn’t always as straightforward as it seems. Like any structural element, there are challenges to consider—but with the right approach, these can be managed effectively.

Let’s explore the typical hurdles and how to overcome them with best practices:

Challenges:

1. Selecting the Right Type of Purlin

With options ranging from c purlins, z purlins, timber purlins, and more, choosing the correct type of purlin can be tricky. Each comes with its unique structural strength, load-bearing capacity, and application scenarios. Using the wrong type may lead to structural issues or limit your design flexibility.

2. Complexity in Design Calculations

Designing the correct spacing of purlins, determining lap length, and ensuring adequate support structures can get complicated, especially in larger steel structures, metal buildings, or buildings with irregular shapes. Miscalculations could compromise the structural integrity of the entire roof system.

3. Material Challenges

Whether it’s sourcing hot-rolled steel, cold-formed steel c, or red oxide purlins, supply chain issues or errors in fabrication and delivery can delay the project. Incorrect or damaged metal purlins, timber panels, or even misaligned c-shaped purlins can slow down installation and increase costs.

4. Installation Difficulties

Getting the purlin span, alignment, and connections (such as single cleats and flange stiffeners) just right requires experienced builders and precise work. Mistakes here can lead to uneven roof surfaces or weak spots, which could fail under the weight of the roof deck or environmental stresses.

5. Environmental Considerations

In regions with high moisture, chemical exposure (like chemical plants), or coastal environments, untreated purlins can corrode. Even a layer of paint may not be sufficient unless it’s a protective red primer like that used in red oxide purlins.

Best Practices

✅ Collaborate with Structural Engineers

Always work with qualified structural engineering professionals. They’ll ensure your purlins—whether z shapes, c purlins, or timber purlins—are correctly calculated for the desired shape, roofing materials, and load requirements.

✅ Use Quality Materials

Invest in high-quality steel purlins like hot-formed steel or cold-formed steel c with protective coatings for durability. For smaller residential builds, carefully selected timber purlins can still be a reliable option.

✅ Follow Manufacturer Guidelines

When using metal purlins, follow the manufacturer’s recommendations for flange stiffeners, spacing of purlins, and lap length to ensure safe and durable installation.

✅ Plan for Environmental Factors

In areas prone to moisture, chemical exposure, or salt air, opt for red oxide purlins or those with specialised coatings. These provide a durable, protective layer against corrosion, especially important in industrial buildings or metal buildings.

✅ Ensure Precise Installation

Use experienced contractors who can:

- Align purlins correctly with the primary framing system.

- Secure them properly with single cleats, bolts, or welds.

- Check alignment with the horizontal frame, ensuring the roof sits evenly.

✅ Regular Quality Checks

Throughout installation, inspect each purlin span, connection point, and component to catch any issues early. Pay attention to support structures like eave struts, parapet rails, and channel sections to guarantee everything fits together seamlessly.

✅ Request a Free Quote

For large projects, ask for a free quote from fabricators or suppliers. This helps with budgeting and ensures you’re getting the right materials, whether for metal roof systems, timber panels, or mixed-material designs.

In summary, while there are challenges in incorporating roof purlins into a building project—especially in larger or more complex steel construction—following best practices will set you up for success.

Roof Truss Installation Guide

The installation process for roof trusses depends on the design system used by your truss supplier. In Australia, the two most common truss design and component systems are Mitek and Pryda. Each has its own specific installation guide, tailored to its proprietary engineering system.

Below is an overview of the installation guide provided by Mitek.

These guides typically arrive on-site in hardcopy, usually packed in an A4 clear ziplock bag. They’re often accompanied by two carpenter’s pencils—with broken leads, of course—making sharpening a frustrating game of whittling to uncover a usable section of lead (if one exists at all).

Despite the humble packaging, the installation guide is essential. It outlines the full sequence of truss installation, including how to correctly install both the trusses and all associated hardware to ensure compliance with the manufacturer's specifications.

This document is not just helpful—it’s required reading! It should be read carefully and followed exactly. Neglecting to do so can void your truss installation warranty and lead to compliance issues. Relying on the mindset of "we've always done it this way" won't suffice if defects arise and an insurance claim is filed. It's imperative to follow the manufacturer's instructions meticulously to ensure compliance and protect yourself from potential liabilities.

Mitek Installation Guide

Pryda Installation Guide (not the DJ if your wondering)

🚀 Different Names for Purlins

You might hear different names thrown around for purlins. Depending on where you are, who you’re talking to, and even the type of construction project, the term “purlin” might have a few alternate names.

Let’s break them down to clear up any confusion:

Common Alternate Terms for Purlins

- Roof Purlins: The standard term you’ll hear in most construction industry discussions. It describes horizontal structural members used to support roofing sheets, metal sheeting, or roof decking.

- Horizontal Beams or Horizontal Bars: These terms are sometimes used by builders or homeowners to describe the horizontal frame elements of a roof. While technically accurate, they’re more general and might refer to other support structures as well.

- C Purlins and Z Purlins: Specific terms used to describe the shape of the purlin cross-section. C-shaped purlins (or just c purlins) and z-shaped purlins (or z purlins) are common in metal buildings and steel construction, where they’re made from hot-rolled Fsteel, cold-formed steel c, or hot-formed steel.

- Channel Sections, U Sections, or U Shapes: These terms might be used in design documents or by suppliers to describe specific purlin profiles. Channel sections are like a squared-off U, and u shapes can refer to shallow channel profiles used for sheet support or door mounting.

- Timber Purlins: In timber frame structures or older buildings, these horizontal beams made from timber panels are sometimes just called “purlins” or even “roof battens,” depending on the region.

- Red Iron: In some regions, particularly in the U.S., you might hear the term red iron used when referring to steel framing members like red oxide purlins that have a red primer coating for corrosion resistance.

- Secondary Framing Components: In larger projects like metal buildings or buildings, purlins are often referred to as part of the secondary framing components—which means they support the primary framing system (like steel beams) and create the framework for the roof.

- Sheet Support, Roof Support, or Purlin Support: More descriptive terms that highlight the purlin’s role in supporting roofing materials, metal sheeting, or roof decking. These might pop up in supplier catalogues, design specs, or even casual conversations on a job site.

Why So Many Names?

The variation in names often comes down to:

- Regional differences: Terms like red iron are more common in certain areas.

- Material differences: timber purlins in traditional timber panels construction versus metal purlins in modern steel construction.

- Industry differences: Commercial builders might refer to purlins as part of the secondary framing components, while homeowners or smaller contractors might just call them “roof supports” or “horizontal beams.”

- Design specifics: Referring to the purlin by its desired shape (like z shapes, c shapes, or u shapes) helps clarify the material’s role and structural profile.

In summary, whether you hear terms like roof purlins, c purlins, z purlins, red iron, or sheet support.

Knowing these different terms can make your conversations with builders, engineers, and suppliers clearer and more confident.

Conclusion

Roof purlins might not get much attention, but they’re essential for keeping your roof strong, stable, and secure. Whether you’re building a home, shed, or steel structure, the right type of purlin helps distribute weight, support roofing materials, and improve durability.

Understanding how they work gives you the confidence to ask the right questions and make smarter choices on your next construction project.

👨🍳😘 - The Chef's Kiss

Not sure if you caught this—but if you’re a fan like I am—Eric Prydz recently dropped “Call on Me” live at a set in Texas. Why mention it? Well, we referenced Pryda above, and that got our DJ brain spinning. So here’s a little DJ-style chef’s kiss to wrap up this post. Enjoy.

🧰 Frequently Asked Questions (FAQ's)

1. What exactly is a roof purlin?

A roof purlin is a horizontal structural member that supports the roofing materials of a building. It’s the beam that runs across the roof, resting on the primary framing system, such as steel beams, walls of the building, or timber frame structures.

2. What types of purlins are commonly used?

There are several types, including:

- C purlins and c-shaped purlins

- Z purlins and z-shaped purlins

- timber purlins for timber panels or timber frame structures

- U sections, u shapes, and channel sections for specific design needs

3. Why are purlins important in construction?

Purlins provide essential structural support, helping to distribute the weight of the roof deck and secure roofing sheets, metal sheeting, or insulation material. They’re vital for maintaining the structural integrity of roofs in metal buildings, industrial buildings, and residential homes.

4. Can I use timber instead of steel for purlins?

Yes, in certain cases. timber purlins are still used in some timber frame structures or traditional homes. However, for longer spans or buildings that need extra structural strength, steel purlins like hot-rolled steel or cold-formed steel c are preferred.

5. What’s the difference between c purlins and z purlins?

C purlins have a c-shaped profile, while z purlins are shaped like a z, offering stronger load-bearing capacity and the ability to overlap (via lap length) for greater span efficiency. Z purlins are often used in larger buildings or roofs with longer spans.

6. Do purlins need a protective coating?

Absolutely. Many metal purlins are treated with a layer of paint or red primer (as in red oxide purlins) to protect against corrosion. This is especially important in areas like chemical plants or coastal environments where moisture and chemicals can be an issue.

7. Who designs and installs purlins?

The design is usually handled by structural engineering professionals, who determine the correct purlin span, material, and placement. Fabricators produce the purlins, and contractors or builders handle the installation, ensuring everything aligns with the design.

8. What challenges should I expect with purlins?

Common challenges include selecting the right type of purlin, calculating the spacing of purlins, sourcing materials like steel purlins or timber purlins, and ensuring proper installation using components like flange stiffeners, single cleats, and support structures.

9. Can purlins be part of energy-efficient designs?

Definitely. Purlins can support insulation material, improve metal roof systems, and help manage temperature control in the building. Their integration with other structural elements can contribute to a more energy-efficient home or commercial building.

10. Where can I get a quote for roof purlins?

Builders, fabricators, and suppliers often offer a free quote for roof purlin materials and installation. Make sure to provide details about your project’s size, roof type, and material preferences to get an accurate estimate.

Further Reading