Introduction – The Energy Promise vs. Reality

Have you ever seen a new home advertised as “energy efficient” or “7-star rated”? It’s almost a given these days. Builders love to tout how their designs will save you money on power bills and keep your home comfy year-round. And fair enough—you’d expect a new build to be better than something from the '70s, right?

But here’s the uncomfortable truth: just because a home is designed to be energy efficient doesn’t mean it actually is once it’s built.

In fact, research shows that some homes use up to 2.5 times more energy than what was predicted in the design phase. That’s a big gap between the promise and the reality—and it's known in the industry as the energy performance gap.

So, how does this happen?

It turns out that most of the trouble starts between the time the plans are finished and when you get the keys. That’s the construction phase—where things like material substitutions, less than awesome workmanship, miscommunication, and rushed installs start to creep in.

The original design might have ticked all the boxes for compliance, but the as-built version? That’s often a different story.

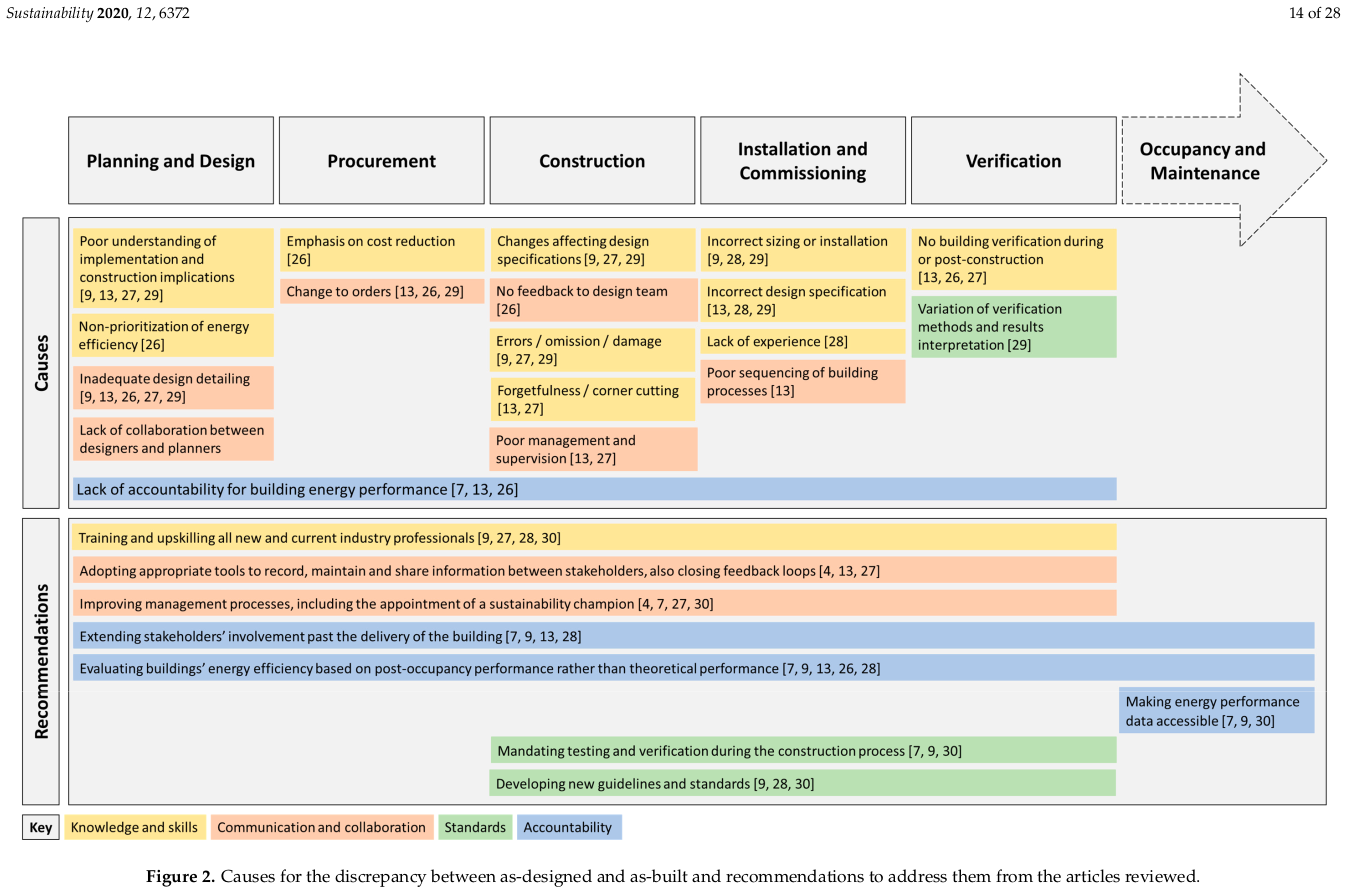

In this post we take a look at a major research review done by Curtin University. They looked at what really causes this performance gap in new builds—specifically in the stage between when your design is done and before anyone moves in. That means procurement, construction, and commissioning—the behind-the-scenes stuff that homeowners rarely see, but which has a huge impact on whether your home lives up to the energy rating on the brochure.

And if you're a first-time builder or just someone trying to make sure your new place won’t bleed money through the walls, this matters—a lot.

What is the Energy Performance Gap?

When a new home is designed, the building certifier comissions an energy assessor to run the design and house details through energy modelling software. These programs look at things like your home’s orientation, insulation, window sizes, and local climate, and then spit out a predicted star rating—usually part of what's required to meet the National Construction Code (NCC).

In Australia, we mostly use the NatHERS (Nationwide House Energy Rating Scheme) system, which rates your home from 0 to 10 stars based on its thermal performance.

But here's the thing: those ratings are based on assumptions, not guarantees.

They assume that the house will be built exactly as designed. That the insulation will be installed as per the manufacturers guidelines. That all the materials will match the plans. That the trades won’t cut corners. That no one will make last-minute swaps. And—let’s be clear—that’s rarely how things go in the real world.

That’s where the energy performance gap (EPG) comes in. It’s the difference between how your house is supposed to perform (on paper), and how it actually performs once it’s built and you’re living in it.

There are a few different ways to measure this gap:

- Regulatory EPG is what happens when a building meets code during design, but not in practice.

- Static EPG compares the design’s performance model to actual energy use.

- Dynamic EPG goes a step further and looks at energy performance over time, comparing ongoing data to the original expectations.

Whichever way you measure it, the conclusion is the same: homes often under perform, and we’re not talking about small margins. In some cases, energy use is double—or even more—than what was modelled.

The problem isn’t just the modelling itself (though it has limitations). It’s that nobody’s checking whether the final home actually lives up to the model. Once the paperwork’s been approved, and "signed off" the system stops caring.

And that’s a big issue for buyers who’ve been sold on the promise of efficiency—but who end up footing the bill for the performance shortfall.

How Design Choices Set the Stage for Construction Failure

Here’s something most people don’t realise: a lot of the problems that show up on site during a build actually start back in the design phase.

Designers, architects, draftsmen, energy assessors, and engineers all play a part in how your home is supposed to perform. They set the energy targets, choose materials, specify insulation levels, and detail how different components—like windows, walls, and roof systems—should fit together.

But there’s a big problem: those plans often don’t match reality.

Sometimes it’s because designers simply don’t have enough hands-on construction experience. They may not fully understand how their design details will work on a real, messy, uneven job site. And the drawings they hand over to the builder might not explain things out clearly enough—so the builder has to make their best guess. That’s when things start to go sideways.

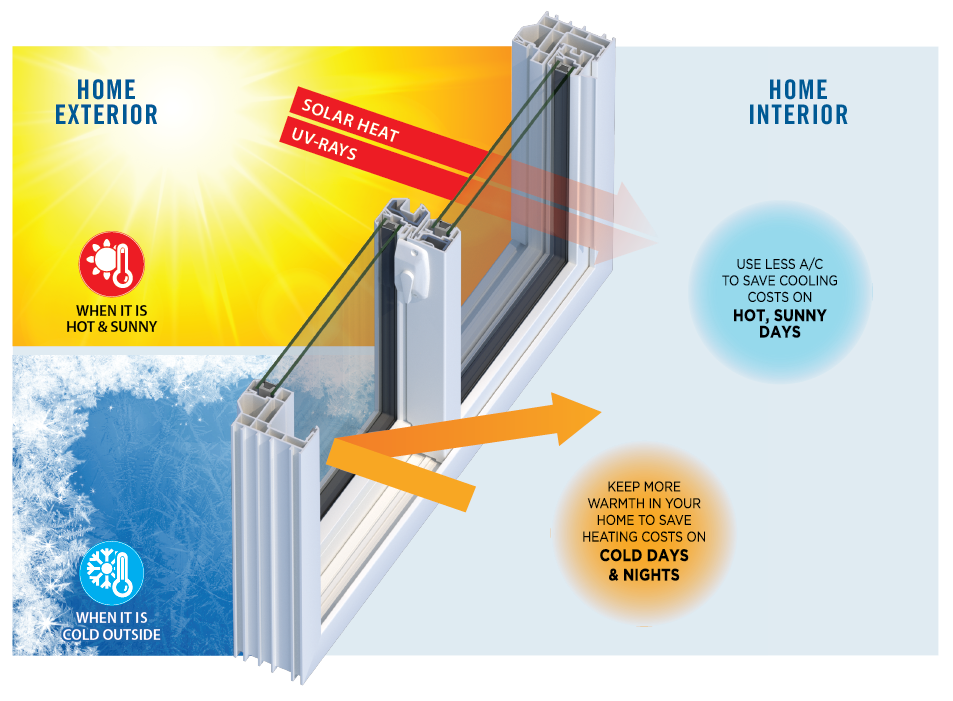

Let’s say a designer draws up a thermal break detail for a steel frame wall. Great idea, but if the drawing doesn’t explain how to install it properly, the trades might skip it altogether—or worse, botch it in a way that creates gaps or thermal bridges. Suddenly, your home’s energy performance takes a hit—and no one’s the wiser.

It’s also common for key energy-saving details to be treated as “nice-to-haves” rather than non-negotiables. Some drawings leave important layers like insulation, vapour/ait/water barrier tapes, or junction details too vague. When these things are unclear, they often get left out, done incorrectly, or replaced with whatever’s easier (or cheaper) on the day.

And then there’s the issue of complexity. Some design solutions are just too fiddly or impractical to build well under normal site conditions. If something’s hard to build, chances are it won’t be done properly—especially if the builder or site supervisor doesn’t understand the energy consequences of taking a shortcut.

The upshot? A well-meaning design can end up being quietly sabotaged by unclear specifications, missing details, or wishful thinking. And the energy efficiency rating you were counting on starts slipping before the slab is even poured.

Procurement – Where Corners Start Getting Cut

So the plans are done, the energy rating is sorted, and it’s time to line up the materials, products, and trades to build your new home. Sounds simple enough, right?

Well—this is actually where a lot of silent damage happens to your home’s energy performance. It’s called the procurement stage, and it’s often where cost-cutting, substitutions, and dodgy decisions sneak in under the radar.

Let’s start with tenders. In most residential builds, whether it's project homes or custom builds, the job tends to go to whoever can do it cheapest. That means subcontractors are selected based on price, not necessarily their skills, experience, or knowledge of energy-efficient construction. The result? You get people on site who might be good at building fast—but who’ve never even heard of thermal bridging or passive design.

Then come the substitutions. Maybe the builder can’t get the specified insulation in time. Maybe the windows that were in the design cost a bit too much. Maybe the client (that’s you) was told a “similar” product would be just as good, but cheaper. So the original specs are swapped out for something else—sometimes without any documentation or re-evaluation of how that change affects performance.

And let’s be clear—most homeowners aren’t trained to know whether a window with a slightly higher U-value or different frame material makes a big difference.

It’s not just about products either. The way services are procured—like who installs the HVAC system or does the ductwork—can also have a major impact. If these trades aren’t looped in early, or if they’re chosen based purely on cost, there’s a high risk they’ll just “make it work” on site without regard for how it affects energy performance.

And because these changes are made during procurement and often happen quietly, they rarely get reviewed by the original designer or energy assessor. So your build drifts further away from the as-designed energy target—and nobody’s the wiser.

👉️ We've discussed AS4254.1, Air conditioning Installation in a previous post you can read about it on the link below.

Construction – Where It All Falls Apart (Literally)

Alright—this is the big one. This is where the rubber hits the road, the frames hit the slab, and the “as-designed” officially becomes the “as-built.”

And let’s not sugarcoat it: this is also where a lot of things go wrong.

The construction phase is full of moving parts. Dozens of trades are involved. Timelines are tight. Materials are missing or late. Decisions are made on the fly. And energy performance? Most of the time, it’s not even on the radar.

Let’s talk numbers for a second. According to the research, the average new home ends up with between 2 and 28 defects—per dwelling.

Some of these are minor, but others have a big impact on thermal performance and energy efficiency. Things like:

- Insulation not installed properly (or missing altogether in spots)

- Air gaps around windows and doors

- Thermal bridging through steel frames or poorly detailed junctions

- Crushed insulation behind pipes or squashed into roof corners

- Vapour barriers and sealing tapes left out, torn, or misapplied

Once the plasterboard goes up, you’ll probably never know that any of this isn't done. These things get hidden, painted over, and forgotten—until your house is freezing in winter, sauna like in summer, and your power bill looks like you’re running a server farm.

Why does this happen?

A few reasons. First, many trades on site just aren’t trained in energy-efficient construction. They might be excellent chippies, sparkies, or plumbers—but if no one’s told them that slicing through a vapour barrier with a saw is a problem, they’ll do it without thinking twice.

Second, the site supervisor might be juggling multiple builds and won’t catch every detail. And even if they do, fixing things properly often takes time, and time is money.

Third—and this one’s frustrating—even when mistakes are spotted, it’s easier to patch over them and move on than to redo the work properly.

But the biggest issue? There’s no quality control process in place that specifically checks for energy performance. Builders check dimensions, waterproofing, and structural stuff (hopefully), but energy integrity? That’s rarely audited.

So unless you're watching your build like a hawk—or you’ve hired someone who will—it’s very easy for a 7-star home on paper to end up being more like 4.5 in real life.

Technology Installation and Commissioning – Set Up to Fail

You’ve made it through framing, cladding, and plasterboard. Things are looking like a real house now. The heating and cooling systems are getting installed. The hot water unit’s going in. Ductwork’s being strung through the ceiling like Christmas tinsel.

But here’s the problem: if this part isn’t done properly, it can sabotage the whole energy performance of the home—even if everything else was perfect.

This stage is called commissioning, and it includes setting up, testing, and tuning all the systems that make your home comfortable and efficient—air conditioning, hot water, ventilation, and solar if you’ve got it.

In theory, each of these systems should be sized and installed based on what the home actually needs. In reality? It’s often a guessing game.

Take air conditioners, for example. Installers will often oversized units "just in case"—because bigger must be better, right? Wrong. An oversized system will short-cycle, wear out faster, and cost more to run. A system that’s too small won’t keep up and will chew through power just trying to keep the house livable.

Same goes for hot water. Got solar thermal or a heat pump? Great—unless it’s been plumbed incorrectly or the storage tank’s set too low, in which case you’ll run out of hot water or burn heaps of energy reheating it.

Then there’s ductwork. You can have R6 insulation in your ceiling, but if the ducts aren’t sealed, insulated, or routed properly, you’re basically piping your cooled or heated air straight into the roof cavity. That’s money blowing out of your metaphorical chimney.

And sadly, most of these things don’t get checked. There’s no standardised test across all residential builds to say, “Yes, this system is set up correctly and performs as intended.” Most of the time, as long as it turns on, everyone walks away.

Worse still, different trades don’t always talk to each other. The duct installer might cut holes in your carefully sealed walls. The plumber might poke pipes through insulation, leaving gaps behind. There’s no one overseeing how it all fits together—unless you or someone you hire takes the reins.

Verification – The Testing That Never Happens

So the build’s finished, the systems are installed, the builder hands over the keys—and you move in expecting a comfortable, energy-efficient home.

But here’s the big question: who actually checked that everything was done properly?

In most cases, the answer is… no one.

Welcome to the missing piece of the energy-efficiency puzzle: verification. That means testing and inspecting the house after it’s built to make sure it performs the way it was designed to.

It sounds like common sense, right? You’d expect someone to double-check that insulation was installed properly, that the building is airtight where it should be, and that systems are running efficiently. But in Australia’s residential construction industry, this kind of post-construction testing is basically non-existent—especially in the volume home market.

There are tools that can help. Ever heard of a blower door test? It’s a fan that gets installed in your front door to measure how airtight your house is—how much air leaks in or out. There’s also thermal imaging, which can show where insulation is missing or where air is leaking. These tests aren’t hard to do, and they’re standard in places like the UK and parts of Europe.

But here in Australia? Unless you’re building a high-performance or certified passive house, odds are your builder doesn’t offer it—and might not even know what it is. The NCC doesn’t require it. And unless you ask (and are willing to pay for it), you won’t get it.

Even when testing is done, there’s no consistent process or benchmark across the industry. One inspector might use different thresholds or test setups than another. And with no formal requirement to pass or fail, the results often don’t lead to action anyway.

So what happens? Builders claim compliance based on documentation, not performance. And if your home isn’t performing well once you’ve moved in, good luck proving it was built incorrectly. By that point, you’re on your own.

What’s Behind All This? A Culture of No Accountability

At this point, you might be wondering: how is this still a thing? If so many homes under perform, if the tools and standards to fix it already exist, and if we’re supposedly designing for efficiency—why hasn’t the industry cleaned up its act?

The answer’s simple and frustrating: no one is really held accountable for energy performance once the home is built.

When a home is being designed, the energy rating is handled by an assessor—usually using NatHERS software. They model it, tick the compliance boxes, and that’s their job done. After that, the baton gets passed to the builder. But here’s the kicker: there’s no requirement for the builder to prove that what they built matches the design. No one checks if the same insulation was used. No one tests the air tightness. No one confirms that services were installed or commissioned correctly.

Then there’s the trades. Each one focuses on their own part of the job—framing, cladding, plumbing, electrical—but very few are thinking about how their work impacts the energy performance of the whole building. And why would they? It’s not in their scope, it’s not on their checklist, and it’s not something they get called out for if it goes wrong.

What’s worse, there’s very little communication across the chain. Design documents don’t always make it clearly through to site. Services drawings get revised mid-build. The HVAC team doesn’t talk to the insulation crew. Important details get lost, misunderstood, or flat-out ignored. And by the time someone notices the home’s not performing as expected, everyone involved has already moved on to the next job.

In commercial or government projects, this kind of thing gets picked up because there are more rigorous handover processes and formal commissioning. But in residential? It’s a free-for-all. Once your final inspection is done (which is mostly about safety and compliance, not energy), you’re on your own.

It’s not that individual builders or trades are malicious. It’s that the system has no built-in mechanism to make sure energy performance actually happens. And if there’s no accountability, there’s no incentive to get it right.

What Needs to Change? The Research Recommendations

So, what’s the fix? How do we go from energy-efficient homes on paper to homes that actually live up to their promise once you’ve moved in?

The good news is, we don’t need to reinvent the wheel. The research spells out clear, practical steps the industry can take to close the energy performance gap. And while these changes won’t all happen overnight, knowing what needs to improve can help you, as a homeowner, ask smarter questions and demand better outcomes during your own build.

Here’s what needs to change:

1. Better Training for Everyone Involved

Designers, builders, site supervisors, and trades all need to understand how their work affects energy performance. Not in a vague, feel-good way—actually knowing why a thermal break matters, how to avoid thermal bridges, what proper insulation installation looks like, and why air tightness isn't just about drafts.

Right now, energy performance is treated like a checkbox task, not a craft that requires knowledge. That needs to change.

2. Real Collaboration, Not Silos

The build process is too disconnected. Designers don’t talk to installers. Trades don’t get briefed on energy goals. Documentation gets watered down or lost along the way. The whole thing needs more coordination.

The fix? A process where everyone’s on the same page from start to finish. That means clear documentation, regular team communication, and feedback loops—especially during construction and handover.

3. Accountability from Start to Finish

Here’s a big one: someone has to own the energy performance outcome. Whether that’s the builder, a project manager, or a third-party verifier—there has to be a point person making sure what was designed actually gets delivered. Without accountability, there’s no incentive to get it right.

This could include tying final payments to performance tests, including commissioning reports in the handover pack, or even introducing energy performance guarantees. (Yes, that’s a thing overseas.)

4. Standardised Testing and Verification

It’s time to normalise post-construction testing. Blower door tests, duct leakage testing, thermal imaging—these are affordable, accessible tools. They’re not science fiction.

The industry needs to adopt them as part of the normal build process. At a minimum, there should be checks on insulation installation, system commissioning, and air tightness before handover. And the results should be documented—not just verbally signed off by someone with a clipboard.

5. Follow the Lead of Smarter Countries

The report references programs from other parts of the world that are way ahead of us. For example:

- Display Energy Certificates in the UK show how buildings actually perform in use—not just what they were designed to do.

- The Soft Landings Framework in the UK helps smooth the handover process by making sure buildings work as intended post-completion.

- Pay-for-performance schemes in the US reward builders or developers when verified performance targets are met.

These systems aren’t perfect, but they show it’s absolutely possible to close the gap—with the right policies, incentives, and industry buy-in.

Why This Matters for Australian Homeowners

If you’re building or buying a new house in Australia, this whole “energy performance gap” might sound like someone else’s problem. Something for policy makers, academics, or industry insiders to deal with.

But it’s not. It’s your problem—because you’re the one living in the house, paying the bills, and dealing with the consequences if it’s not built right.

And here’s the thing: Australia’s building code (the NCC) and our rating tools (like NatHERS) still focus mostly on theoretical energy use. They don’t really care how your home performs once you move in. There’s no national requirement for real-world testing. And if the builder says it’s a 7-star home—well, that’s usually good enough to tick the compliance box.

The gap between what’s designed and what’s delivered? It’s hidden behind the plasterboard. You won’t see it until your energy bills arrive or until your ducted air-con can’t keep up on a 40-degree day.

This matters because:

- You might be paying for features you’re not actually getting.

- Your home might not be as comfortable or healthy as promised.

- You're likely spending more on heating and cooling than you should.

- And worst of all—you won’t know any of this until it’s too late to fix cheaply.

So, what can you do?

- Start by asking better questions.

- Get your builder to confirm that the materials used on site match what was on the energy assessment.

- Ask if the trades are briefed on performance expectations.

- Request documentation during and after the build.

- If you can afford it, consider bringing in a third-party inspector to check key details—especially insulation, air sealing, and system commissioning.

Even simple things, like walking through your home before the plaster goes up and checking insulation coverage, can make a huge difference. It’s not about being annoying—it’s about protecting your investment.

Because let’s face it: you’re the one who has to live with the result.

Conclusion – Getting the Home You Think You're Building

Here’s the truth that no one really tells you when you start building a new home: what’s on the plans is not always what gets built.

And when it comes to energy efficiency, that gap between “what was supposed to happen” and “what actually got delivered” can make all the difference in how your home feels—and what it costs to run.

The research is clear: homes that are energy-efficient on paper often fall short in the real world. Not because of one big problem, but because of dozens of small ones. Confusing designs. Product swaps. Poor workmanship. Trades not being looped in. Systems not being tested. A lack of follow-through. And, above all, a system that doesn’t hold anyone accountable for delivering the energy performance you thought you were getting.

But here’s the thing—this isn’t an unsolvable mystery. We already have the knowledge, tools, and processes to build homes that genuinely perform. Other countries are doing it. Some builders here are doing it too. It’s not magic—it’s just good practice, applied consistently.

For now though, in Australia’s residential market, the burden mostly falls on the homeowner to stay alert, ask questions, and push for quality. It shouldn’t be that way—but it is.

So if you’re building a new home and want to avoid energy performance disappointment, here’s the simplest advice:

- Be involved in the process.

- Don’t assume it’s all being done right.

- Ask for proof—not just promises.

- And wherever possible, document everything.

Because when the summer hits 40 degrees or winter mornings dip below freezing, it won’t be the brochure or the energy rating that keeps you comfortable. It’ll be how well your home was actually built.

Frequently Asked Questions

1. What is the energy performance gap (EPG)?

It’s the difference between how energy-efficient your home is supposed to be (based on design and modelling) and how it actually performs once built and lived in.

2. Why does the energy performance gap happen?

Because what’s designed doesn’t always get built the same way. Subpar installation, material swaps, rushed trades, or missing details can all reduce your home’s actual performance.

3. Does the NCC or NatHERS ensure my home will perform well?

Not really. These tools and codes assess theoretical performance, not real-world results. There’s no required post-build testing to prove your home performs as rated.

4. How do I know if insulation or air sealing was done properly?

Ask to inspect insulation before plasterboard goes up. Request photos or hire an independent inspector. Don’t rely solely on the builder’s word—check for yourself.

5. Are product substitutions during the build a big deal?

They can be. Not all insulation, windows, or wall systems are equal. If something is swapped out, ask for the specs and how it compares to the original design.

6. What is commissioning and why does it matter?

Commissioning is the process of setting up and testing systems like heating, cooling, and ventilation. If skipped or done poorly, even top-quality systems won’t work efficiently.

7. Can I ask for energy performance tests on my home?

Yes. Tests like blower door testing and thermal imaging are available through independent assessors. They’re not standard in residential builds, but they should be.

8. Is it worth paying extra for third-party inspections?

Absolutely. A few hundred dollars now could save thousands in energy costs later—not to mention make your home more comfortable and durable.

9. Who’s responsible if my home under-performs?

That’s the tricky part—currently, no one is legally responsible unless your contract specifically says otherwise. That’s why it’s important to ask for documentation and quality checks during the build.

10. What’s the one thing I should do right now if I’m about to build?

Start asking questions. Get clear on what products and systems are being used, how they’ll be installed, and how performance will be verified—before the slab goes down.

Further Reading