What is a short stud or cripple wall?

- Short stud: A wall stud that doesn’t run the full distance between bottom plate and top plate. You’ll see:

- Under-window short studs carrying the window sill down to the bottom plate.

- Above a door opening (or window) short studs carrying the header up to the top plate.

- Cripple wall (short timber wall): A short wall that lifts the first floor (the living area of the home) above the top of the foundation, often forming the crawl space of the property. It connects floor joists and rim joist to the home’s foundation.

Where and when you need one

- Openings in timber stud walls

- Windows: Short studs under the sill support loads and help prevent sagging or racking.

- Doors: Short studs above a door opening (between the header and the top plate) keep the opening plumb and help spread loads to the adjacent king stud and jack stud.

- Raised floors & crawl spaces

- Cripple wall foundation: If your first section of the home sits over a crawl space (common in older homes), a short timber wall supports the floor system and acts as part of the foundation assembly.

- Renovations and extensions

- When cutting in a new window or widening a door, you’ll almost always introduce short studs somewhere—either above the header or below the sill—to regain stiffness.

- Seismic regions

- In areas with regular seismic activity, short walls under floors must be detailed so they don’t behave as a “soft storey.” Proper detailing helps prevent total collapse in the event of a large earthquake.

Regional names and how to translate the lingo

- On site, people still say “cripple studs.” Many tradies prefer “short studs.”

- Around openings you’ll also hear:

- King stud: full-height stud that flanks the opening.

- Jack stud (trimmer): supports the header directly.

- For the underfloor wall:

- Cripple wall is still common, but some pros will say “short wall” or “underfloor short wall.”

- Building compliance officials and local building code documents (increasingly accessed as digital codes) may use a mix; when in doubt, check the NCC and AS1684.

Common field challenges (and why failures happen)

- Weak cripple walls in older homes

A home’s cripple wall without adequate bracing can buckle during violent movement, allowing the living area of the home to slide off the top of the foundation. - Misaligned load paths around openings

Short studs that don’t align with headers, sills, or adjacent king/jack studs interrupt load flow. Over time that can twist frames, jam doors, and crack finishes. - Service clashes

Water lines and utility lines weaving through the inside of the stud walls can notch or bore short studs in the worst spot. Over-notching reduces the cripple wall’s load-bearing capacity in that bay — a hidden structural issue. - Irregular spacing

Changing window sizes or moving a door opening mid-install can leave “creative” short-stud spacing. Uneven spacing reduces sheet bracing performance at the top of the stud wall and can ripple into the bracing layout. - Poor connections to the foundation

Underfloor short walls need proper continuity to foundation anchors and the home’s foundation. Missed anchorage or rotten sill plates can turn a short wall into a cripple zone rather than extra support. - Code drift and missing documentation

Site Crews guess instead of checking local building code references. With digital codes (and tools) widely available, there’s no reason not to pull the latest section during QA.

Best practices & recommendations

- Plan the load path on paper first

Mark the top plate, bottom plate, openings, king stud and jack stud locations, then place short studs at consistent centres (e.g., 300/450/600 mm to match cladding and window sizing). An efficient and through through layout goes a long way toward keeping openings true. - Treat the underfloor short wall as part of the foundation system

Think of the underfloor short wall as part of the foundation: verify foundation anchors, sill condition, and continuity from the top of the foundation up to the rim joist and floor joists. - Respect services

Pre-route water lines and utility lines to avoid heavy notching/drilling in short studs (1/3 width maximum notch size under standards). If you must drill, keep holes small, centred, and within code limits; reinforce (fish plate/additional studs) where required. - Keep cladding continuous where possible

On short walls, continuous cladding with proper edge support improves racking resistance and overall structural stability of exterior walls. - Use the code you’ll be inspected against

Clarify the local building code edition and print the relevant pages using content printing and section level printing controls so the team installs to the same playbook you’ll be inspected to. - Earthquake retrofitting for older homes

Properly braced and anchored short walls drastically cut the chance of sliding or total collapse. Search for regional programs that support foundation repair, cripple wall retrofits, or seismic events mitigation.

Project types where short studs and cripple walls show up

- Older homes with crawl spaces: The classic cripple wall foundation between the street level and first floor. Check anchorage and wall bracing.

- Modern residential construction: Any door opening or window needs short studs either above or below the opening; metric layouts help your content printing of shop drawings match the work on site.

- Light commercial and mixed-use renovations: Partition rework, new storefront windows, or infill at the street level often rely on short studs to reinforce exterior walls impacted by openings.

- Post-event repairs: After seismic activity or storm events, assess short walls and openings for racking, cracked plates, or displaced anchors before finishing surfaces.

Conclusion

Short studs and short underfloor walls may look modest, but they do an important role in keeping openings square and the living area of the home safely tied to the home’s foundation. In everyday framing, cripple studs help doors shut cleanly and windows glide without binding.

Plan the load path from the top plate to the bottom plate (and into the foundation), coordinate openings with king stud and jack stud positions, and treat the underfloor short timber wall as part of the foundation—complete with sound foundation anchors, continuous cladding/bracing where required, and careful routing of water lines and utility lines along the inside of the stud walls.

A little forethought goes a long way toward avoiding structural issues, inspection headaches, and expensive foundation repair later.

FAQs:

1) What exactly is a “short stud”?

A short stud is a partial-height wall stud used under a window sill or above a door opening—it doesn’t run full height between bottom plate and top plate. It carries loads to adjacent framing so openings stay plumb.

2) What is a “cripple wall”?

A cripple wall is a short timber wall between the top of the foundation and the first floor. Common in older homes, it creates a crawl space of the property and connects the floor joists and rim joist to the foundation. In earthquakes, poorly braced short walls are a good chance for problems.

3) Are there other names for these parts?

Yes. Many pros prefer short stud instead of “cripple stud.” Around openings, you’ll hear king stud (full-height beside the opening) and jack stud (trimmer supporting the header). The underfloor wall may also be called a short wall or underfloor short wall.

4) When do I use short studs above a door or window?

Whenever you create an opening in timber stud walls, short studs fill the space between the header and top plate (above) or the sill and bottom plate (below). They help distribute loads and provide fixing for cladding and linings.

6) What’s involved in a cripple wall retrofit?

Typically: verify sill condition at the top of the foundation, add or upgrade foundation anchors, install code-compliant bracing, and ensure a clear load path to the rim joist and floor joists.

7) How do services like water lines affect short studs?

Penetrations through short studs can weaken a bay, especially near an opening or in a home’s cripple wall. Plan water lines and utility lines routing early; keep holes within local building code limits and reinforce if necessary so you don’t reduce the cripple wall’s load-bearing capacity.

8) Do local codes specify spacing and bracing?

Yes. Local building code (often accessed as digital codes) governs spacing, bracing, anchorage, and sheathing. Use section level printing controls and content printing to share the exact clauses with the crew. Metric layouts (e.g., 300/400/600 mm centres) help coordinate framing and sheet sizes.

9) Where are cripple walls most likely in a house?

At the perimeter, between the street level and the first section of the home (the floor platform). You’ll see them lifting the living area of the home above grade to form a crawl space.

10) Is upgrading a cripple wall a cost-effective way to improve safety?

Generally, yes. Proper earthquake retrofitting—anchorage, bracing, and sheathing—can be a cost-effective way to add extra support, reduce earthquake damage, and help prevent total collapse. Always verify design and detailing against your local building code.

Further Reading

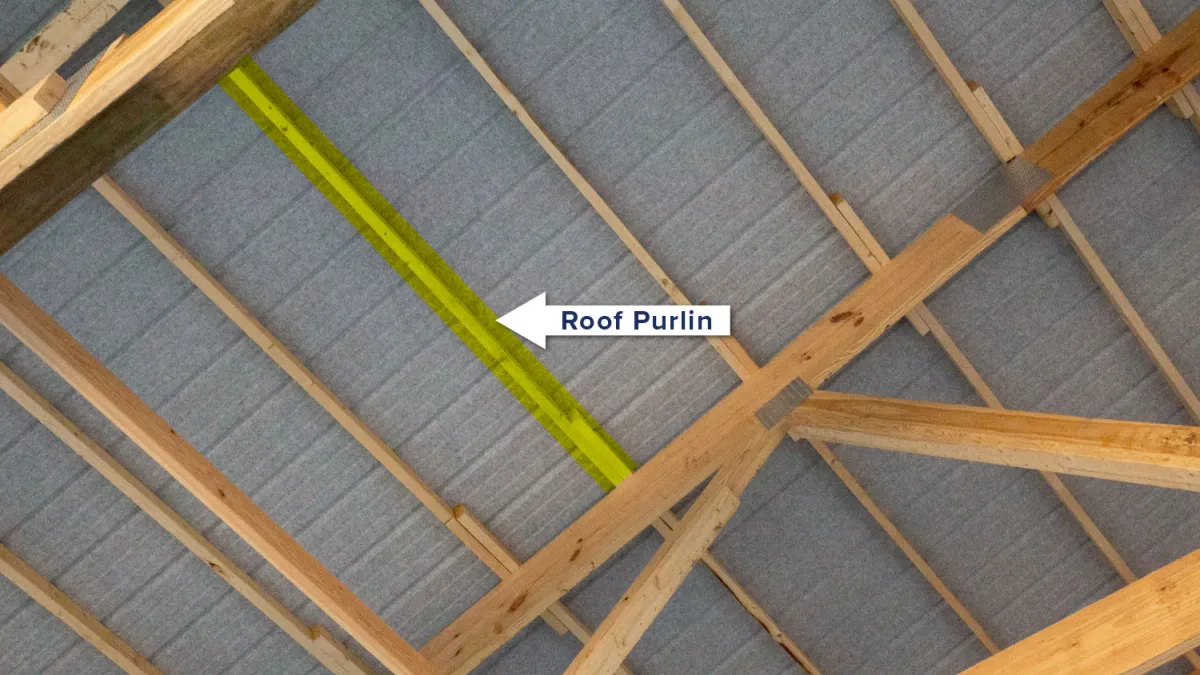

I just like that image 😄

Member discussion