Why steel-cap sneakers for construction work matter on real job sites

If you’ve spent any time on a job site, you know your feet take a beating. Long walks across concrete floors, up and down stairs, in and out of utes or pick up trucks, and hours standing on smooth floors or gritty construction areas—that’s the daily work environment.

The right safety footwear can be the difference between finishing your shift feeling fine or limping to the truck. For 2025, there’s a growing wave of steel-cap sneakers that combine certified protection with the comfort and agility of a running shoe.

Think of them as the perfect blend of comfort and compliance: the toe protection you expect from steel toe boots with cushioning, breathability, and good traction that feels familiar from everyday trainers.

This guide breaks down when a sneaker-style safety boot makes sense on construction sites—and when a traditional steel-toe boot or western-style work boots are still the best option. We’ll cover what to look for in safety features like electrical hazard protection, slip-resistant outsoles, puncture resistance, and ankle support.

You’ll also get a quick breakdown of comfort tech—cushioned insoles, memory foam insole options, EVA midsoles, and arch support—so you can find the right pair for long days on smooth surfaces or dusty slabs.

We’ll shortlist our top pick and four close contenders for the best steel toe shoes in 2025, using a transparent scoring method aligned to the realities of cement construction, light fit-out, and other type of work you actually do. Expect plain-English pros and cons, what each model does best (from wet conditions and cold weather to indoor food service crossover), and where sneaker PPE simply isn’t appropriate.

Along the way, we’ll translate industry standards into practical decisions: what steel toe caps, alloy safety toes, and composite safety toe options really mean; whether a rubber outsole or rubbery soles help on wet tiles; how breathable materials manage body heat; and why high-quality materials like a full-grain leather upper can earn extra points for durability.

By the end, you’ll know exactly when a sneaker-style pair of work shoes is the best choice, how to avoid foot injuries (including plantar fasciitis flare-ups), and what separates the most comfortable steel toe shoes from the rest. Let’s find the right sneaker that keeps you upright, dry, and supported—without feeling like you’re dragging bricks on your feet.

What are steel-cap sneakers?

Definition:

Steel-cap sneakers (often marketed as safety shoes or safety footwear) are athletic-style work shoes that hide steel toe caps inside a sneaker-like upper.

They aim to deliver the perfect blend of comfort (think running shoe feel) and job-ready protection that meets safety standards. Compared with traditional steel toe boots or western-style work boots, these shoes prioritise light weight, flexibility and breathability, while still guarding against toe-impact/compression and—on the right models—electrical hazard protection and puncture resistance.

Common materials you’ll see:

- Toe protection: Mostly steel toe caps; some models use alloy safety toes or a composite safety toe (fibreglass, carbon, or other composite material).

- Midsoles: Cushioned EVA midsoles, sometimes with a stabilising shank (steel shanks or fiberglass shanks) and/or puncture plate.

- Outsoles: Rubber outsole with slip-resistant outsole tread; some brands license tyres-inspired compounds for good traction on smooth surfaces and wet conditions.

- Uppers: Breathable materials (mesh/knit) for heat, or a tougher full-grain leather upper for abrasion and better water resistance.

- Footbeds: Cushioned insoles—often memory foam insole—plus arch-shaping for arch support and maximum comfort on long days.

When you need steel-cap sneakers (project types & tasks)

Great fit for:

- Interior fit-outs and light framing: clean slabs, smooth floors, cement construction environments with lower trip hazards.

- Warehouse & logistics: long walk distances on flat ground, flat outsoles help; focus on slip-resistant outsole and electrical hazard protection.

- Service trades (HVAC, data, light electrical) and first responder light-duty support roles when a shoe—rather than a boot—meets policy.

Use caution / likely not appropriate:

- Heavy demo, rebar jungles, excavation: you’re dealing with sharp steel, unstable substrates, and high-impact hazards—most sites demand boots with ankle coverage and aggressive lugs.

- Outdoor jobs in deep mud, uneven terrain, or cold weather where a waterproof membrane, tall collar and insulation matter.

- Hot works or heavy material handling where metatarsal protection, tall shafts and heat-resistant soles are specified.

What a steel-cap sneaker must have to be comfortable and safe

- Toe room & widths: Look for ample room so steel doesn’t “pinch.” A wider, anatomical last helps avoid foot injuries and flare-ups like plantar fasciitis.

- Midsole + shank: Balanced EVA midsoles with a mild rocker to ease stride. A non-metallic or steel shank adds ankle support and torsional control on ladders.

- Outsole & traction: A slip-resistant outsole (often SR/SRC type testing) with sipes or channels that shed dust and water.

- Protection package: Verified ASTM standards (toe impact/compression) plus electrical hazard protection where required. For sharp job sites, choose puncture resistance.

- Upper & climate control: Breathable materials help with body heat indoors; choose coated leather or a waterproof membrane for wet conditions outdoors.

- Insole & support: Removable cushioned insoles and arch support keep you steady during long days. Swap to your preferred orthotic if you need extra support.

- Weight: Lighter shoes reduce fatigue but shouldn’t be flimsy. You want a pair of work shoes that still feel planted on smooth surfaces.

Why use steel-cap sneakers in construction (benefits)

- Day comfort: Compared with many boots, sneaker-style safety shoes offer lower weight, more flex, and better shock absorption—ideal on concrete floors and smooth floors.

- Compliance through comfort: Workers tend to keep PPE on when it’s comfortable—meaning fewer rule-bending swaps to non-compliant trainers.

- Athletic stability: Modern athletic performance technologies provide lateral support and consistent grip from rubbery soles.

- Versatility: For mixed-duty days—office to job site to warehouse—steel-cap sneakers are the best choice for many roles.

Challenges & trade-offs (what to watch out for)

- Ankle coverage: Lower collar equals less roll protection vs best work boots.

- Puncture protection: Not every shoe includes a plate; confirm spec sheets.

- Water management: Many sneaker uppers are only water resistant. If you’re often in slurry or rain, pick a waterproof membrane model or wear boots.

- Outsole wear: Fine aggregate can sandpaper soft compounds—watch tread depth.

- Fit variance: Steel caps don’t “stretch.” Test with your work socks; check arch support and pressure over the cap.

- Site rules: Some sites ban sneaker PPE outright—policy beats preference.

5 best steel-cap sneakers in the market (2025 comparison guide)

Our weighted selection criteria (totals = 100%)

- Comfort (fit, cushioning, pressure points) — 25%

- Slip resistance & outsole durability — 20%

- Protection (ASTM F2413 toe, EH, puncture plate if present) — 20%

- Build quality & materials longevity — 15%

- Weight & all-day fatigue — 10%

- Breathability & moisture management — 5%

- Value (price/widths/warranty/availability) — 5%

Scoring method: We assign 1–5 per criterion, multiply by the weight, and express a weighted total (0–100). Notes explain where the shoe earns extra points in real-world work environment use.

1) Timberland PRO Intercept Athletic Steel-Toe Work Sneaker (Low & Mid)

- Why it’s here: A true athletic steel toe sneaker line with electrical hazard protection, slip-rated outsole and brand comfort tech for all-shift wear. Product pages list steel safety toe, EH, and SR outsole, with mid-cut options for a touch more ankle support.

- Best for: Indoors, light fit-out, warehouse on smooth surfaces/concrete floors.

- Pros: Light, flexible, solid SR traction; available wides; optional puncture-resistant plate on some SKUs; breathable ripstop uppers.

- Cons: Mesh uppers are mostly water resistant, not fully waterproof; outsole compound favours flat terrain over mud.

Scores: Comfort 4.5/5; Slip 4.5/5; Protection 4.0/5; Build 4.0/5; Weight 4.5/5; Breathability 4.0/5; Value 4.0/5 → Weighted total: ~88/100

2) Reebok Work Sublite (RB4443) Steel Toe Athletic Work Shoe

- Why it’s here: Long-running favourite for “most comfortable steel toe shoes” claims thanks to Sublite EVA cushioning, slip-resistant outsole, electrical hazard/static-dissipative options, and ASTM F2413 listing.

- Best for: Long walk shifts, smooth floors, food service cross-duties where SR matters.

- Pros: Very light, responsive midsole; cushioned insole with removable footbed; SD/EH variants; low bulk around the cap.

- Cons: Not a mud runner; leather/mesh uppers are water resistant at best; outsole lugs are tuned for indoor/flat work.

Scores: Comfort 4.7/5; Slip 4.3/5; Protection 4.0/5; Build 3.9/5; Weight 4.7/5; Breathability 4.1/5; Value 4.0/5 → Weighted total: ~89/100

3) Skechers Work Skech-Air Envoy ST “Arcket” (Steel Toe)

- Why it’s here: ASTM-listed steel toe, electrical hazard protection, slip-resistant outsole, and Air-Cooled memory foam insole under a visible airbag midsole; some versions add licensed Goodyear outsoles for enhanced grip.

- Best for: Indoor-to-dock days with occasional wet conditions on painted concrete or tile—traction is a highlight.

- Pros: Cushioning feel out of the box; stain-resistant treatments; widely available.

- Cons: A touch heavier than ultra-light rivals; styling is bold; not a full waterproof shoes spec.

Scores: Comfort 4.4/5; Slip 4.6/5; Protection 4.0/5; Build 4.1/5; Weight 4.0/5; Breathability 3.9/5; Value 4.1/5 → Weighted total: ~87/100

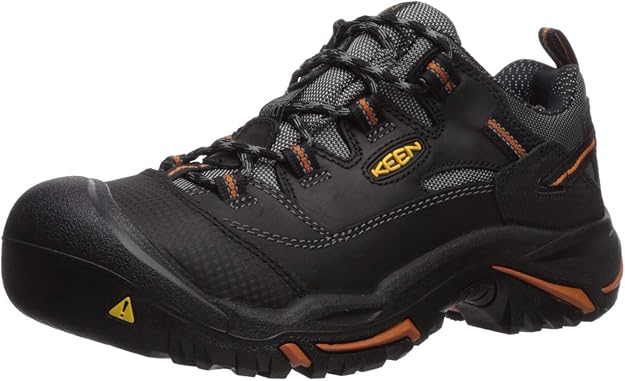

4) KEEN Utility Braddock Low (Steel Toe Shoe)

- Why it’s here: KEEN’s “American Built” steel-toe work shoe with roomy anatomical toebox and KEEN.Grip slip outsole—positioned for indoor job site use and medium-duty tasks; product pages reference ASTM compliance and oil/slip resistance.

- Best for: Medium-duty facility and light construction sites where a tougher leather upper outlasts knit/mesh.

- Pros: Roomy toe box (ample room), robust leather, durable outsole; KEEN’s protective bumper reduces scuffing.

- Cons: Heavier than knit sneakers; breathability lower than mesh; styling reads “work shoe,” not athletic.

Scores: Comfort 4.2/5; Slip 4.3/5; Protection 4.2/5; Build 4.5/5; Weight 3.8/5; Breathability 3.6/5; Value 4.0/5 → Weighted total: ~86/100

5) Timberland PRO Intercept Mid (CSA/Steel Toe variant) — puncture-plate option

- Why it’s here: The Intercept Mid in certain markets lists steel safety toe, EH, SR outsole, and a steel puncture-resistant plate on select SKUs—useful for light debris areas that still warrant plate protection.

- Best for: Mixed indoor/outdoor with more stray fasteners or sheet edges where a plate adds confidence.

- Pros: Familiar Intercept comfort with extra underfoot defence; mid-cut gives mild ankle support.

- Cons: Availability differs by region; plate adds a bit of weight and stiffness.

Scores: Comfort 4.3/5; Slip 4.4/5; Protection 4.4/5; Build 4.2/5; Weight 3.9/5; Breathability 3.8/5; Value 3.9/5 → Weighted total: ~86–87/100

Overall winner (2025): Reebok Work Sublite (RB4443) Steel Toe

Why it wins: For all-day inside work on concrete floors and other smooth surfaces, it combines EVA midsoles pop, low mass, cushioned insoles, and ASTM F2413/slip-resistant outsole/EH listings in a package trades actually enjoy wearing. If your day is 90% indoors with occasional dock runs, this is the best steel toe shoes line we’d recommend first.

Runner-up: Timberland PRO Intercept (Low or Mid) — nearly as comfy, with wider sizing and optional features (including plate on some SKUs) that suit a broader work environment.

Conclusion

If your day is spent mostly on smooth floors and concrete floors—fit-outs, warehouses, facility maintenance, or light service work—steel-cap sneakers can be the best choice.

They bring athletic performance technologies (lightweight foams, tuned EVA midsoles, and breathable uppers). The result is a perfect blend of comfort and protection: steel toe caps or alloy safety toes, electrical hazard protection, and slip-resistant outsole formulas that deliver good traction on smooth surfaces and epoxy-coated slabs.

Still, context matters. If your type of work involves sharp debris, ankle-twisting ground, or constant wet and mud, a taller steel-toe boot or western-style work boots with deep lugs and (often) Goodyear welt construction are the safer bet. Don’t ignore care—rotate pairs, keep uppers water resistant or use a waterproof membrane model for wet conditions, and replace when tread is gone or the midsole collapses.

From our 2025 shortlist, Reebok Work Sublite earned top pick for all-day indoor comfort and verified protection; Timberland PRO Intercept (Low/Mid) ran neck-and-neck, especially where puncture resistance plates are available. KEEN shoes (Braddock Low) brought leather durability and a roomy toe box for those who need maximum comfort across wider feet or worry about plantar fasciitis. Skechers Work impressed with grippy compounds (even Goodyear-branded rubber on some SKUs) and a forgiving memory foam insole feel.

FAQS

1) Steel toe, alloy toe, or composite toe—what’s the best option?

- Steel toe caps: thin profile, very durable, time-tested.

- Alloy safety toes (e.g., aluminium/titanium): lighter than steel with similar strength.

- Composite safety toe / composite material: light and non-metallic (no cold transfer, metal detectors friendly).

Pick based on site rules, comfort, and hazards;

2) Are steel-cap sneakers safe on ladders and platforms?

They can be. Choose models with torsional support (shanks—steel shanks or fiberglass shanks) and a stable midsole. Avoid ultra-soft plush shoe designs that twist under load. A mildly rigid platform with flat outsoles improves stance on rungs.

3) What if my site floors get wet or oily?

Prioritise a proven slip-resistant outsole on a rubber outsole (some use tyres-inspired rubbery soles). For frequent wet conditions, step up to leather or coated uppers, waterproof shoes with a waterproof membrane, or simply switch to boots when puddles or slurry are constant.

4) How do I reduce foot pain (arch pain or plantar fasciitis) in sneakers?

Start with the right last shape (ample room in the toe box) and supportive arch support. Add cushioned insoles—many include memory foam insole layers—but don’t be afraid to swap to a firmer orthotic if you need more control. Rotating pairs helps foams rebound and prevents body heat from breaking them down too quickly.

5) When should I avoid sneaker-style safety shoes altogether?

Heavy demolition, rebar mats, excavation, and uneven ground demand higher collars, aggressive lugs, and often met guards—classic steel toe boots (sometimes a composite toe boot) are safer. Also respect site mandates; some construction sites require boots regardless of conditions.

6) Are leather uppers always better than mesh?

Not always. A full-grain leather upper usually lasts longer against abrasion and keeps feet drier (water resistant by nature, even before membranes). Breathable materials (mesh/knit) cool better indoors but can soak up grime. Choose the upper for the task.

7) What’s the typical lifespan of steel-cap sneakers?

Highly variable: 6–12 months for daily cement construction and warehouse duty is common. Watch for outsole wear, midsole collapse, cap exposure, and delamination. Replace sooner if good traction fades.

8) Is there any advantage to brands known for boots (e.g., KEEN/Timberland/Red Wing)?

Often, yes. Boot-heritage brands bring proven compounds, last shapes, and durability cues into sneaker lines. KEEN shoes prioritise toe box space, Timberland leans into athletic comfort, and Red Wings offers leather know-how—even if the sneaker styles differ from their classic lines.

Further Reading