Walk past any busy construction site and you’ll likely see a tall silhouette turning slowly against the sky—a construction crane lifting heavy materials to great heights. From placing steel beams on tall buildings to flying concrete slabs into position, cranes play an important role in preserving lower backs across construction projects of all sizes.

They multiply human effort through simple machines—pulleys, levers, gears—giving us the mechanical advantage to move heavy objects safely and efficiently.

In this post we break down what cranes are, when you need one, their key components, different types of cranes, how they’re installed and operated, and the digital tools that keep crane safety front and centre. Whether you’re new to the construction industry or brushing up for the work site, you’ll get a clear picture of how these machines do what they do—day in, day out.

What Is a Construction Crane?

A construction crane is a machine designed to lift and place loads—heavy loads, heavy weights, and long construction materials—with precision.

Most cranes do three core things:

- Hoist: Raise or lower a load via wire rope (steel steel cable) and pulley systems powered by an electric motor or hydraulic systems.

- Luff: Adjust the angle or length of the boom (on many crane booms, especially luffing cranes and telescopic boom models).

- Slew: Rotate the working arm (jib/boom) left or right using a slewing unit so you can reach different parts of the work site.

You’ll hear various names: tower cranes, mobile crane, truck-mounted cranes, crawler crane, luffing cranes, t-tower cranes (a common catalog shorthand for T-shaped hammerhead tower cranes), and modern tower crane (a newer generation with advanced controls).

Different names reflect different layouts, crane components, and use cases—but the basic principles are similar: controlled movement of a crane’s load to the right spot, at the right time, with the right safety measures.

When Do You Need a Crane?

You need a crane when your project involves heavy objects or tasks at great heights where manual or small equipment won’t cut it—such as:

- High-rise buildings and tall buildings needing steel beams, façade units, or concrete slabs lifted to the higher level floors.

- Large structures like stadiums, bridges, and industrial plants (heavy modules, long piping spools, pre-cast components).

- Constrained construction site logistics where a crane enables faster, safer placement of construction materials.

- Remote or rooftop installs where heavy-lift helicopters are the only alternative—and often costlier—option.

What’s Included: Core Components of a Tower Crane

While different types of cranes vary in layout, a typical modern tower crane includes these core components and crane parts:

- Crane’s base / base of the crane / crane’s base: Usually a large concrete foundation designed by a temporary works or structural engineer to resist overturning and uplift.

- Crane tower (mast): Stacked mast sections bolted together to reach the needed height.

- Top of the mast / top of the crane: Where the slewing unit sits, allowing 360° rotation.

- Working arm (jib): The long long arm that carries the end of the boom and the crane hook (with a safety latch).

- Counter jib / back of the crane: Holds concrete blocks (counterweights) and sometimes the hoist machinery.

- Operator’s cab with control panels: The crane operator monitors loads, load moment indicators, control system readouts, and wind speed; they make precise crane movements for safe operations.

- Wire rope / steel cable & pulley systems: Provide mechanical advantage for lifting.

- Electric motor and/or hydraulic mechanism (hydraulic cylinders, hydraulic jacks, hydraulic fluid): Power hoisting, luffing, and sometimes climbing systems.

- Climbing frame (on climbing cranes): Lets the crane “grow” by inserting new tower sections using the internal climbing method (within the building core) or external climbing method (outside the building).

Who Designs and Manufactures Cranes?

- Manufacturers (OEMs): Global crane company brands design and build construction cranes—including tower, truck-mounted cranes, crawler crane, luffing cranes, and smaller cranes.

- Engineers: A project’s structural or temporary works engineer designs the concrete foundation or base attachment, evaluates tie-backs to the structure, and checks the maximum amount of weight and overturning forces.

- Construction companies & rigging partners: Coordinate selection, transport (often via flatbed trucks for boom sections and mast sections), assembly, and regular inspection.

- Crane operators & training: Skilled crane operators are licensed and trained—through union halls, accredited schools, and regional programs to run the equipment and enforce crane safety at the work site.

Why Use a Crane? (Benefits That Matter on Real Jobs)

- Productivity: Move heavy materials faster. A single mobile crane or tower crane can replace hours of manual handling.

- Reach & height: Access areas a telehandler can’t—across long arm radii and to great heights on high-rise buildings.

- Precision: Modern controls provide precise crane movements at the end of the boom, easing install of delicate façade panels, MEP skids, and rebar cages.

- Safety: Reduces manual lifts of heavy weights and awkward loads, when paired with proper safety features and safety measures.

The Main Types of Construction Cranes (At a Glance)

- Tower cranes (hammerhead / t-tower cranes): The urban standard for tall buildings. Tall crane tower, fixed base, long horizontal jib with counter jib.

- Luffing cranes: A tower type with a jib that pivots up and down for tighter sites.

- Mobile crane / truck-mounted cranes: Roadable, set up quickly, ideal for short-duration picks.

- Crawler crane: Tracks instead of wheels, strong picks, great for soft ground and large infrastructure.

- Telescopic boom cranes: Sections of boom slide to change the length of the boom quickly.

- Smaller cranes: Compact city cranes, mini crawlers—handy where space is scarce.

Digital & Tech: The Brains Behind Efficient Crane Operations

Modern cranes are more than steel and bolts—they’re smart machines designed for efficient crane operations and safe operations:

- Load Moment Indicators (LMI): Real-time capacity checks based on radius, length of the boom, and crane’s load. They help prevent overloads beyond the maximum amount of weight allowed.

- Anemometers (wind sensors): Continuous wind speed monitoring to manage high winds risk.

- Anti-collision zones: Geofenced envelopes that prevent two cranes’ jibs from intersecting on dense sites.

- Integrated control system & control panels: Diagnostics, fault codes, and precise drive control for smooth, precise crane movements.

- Telematics: Remote performance tracking and maintenance alerts for regular inspection schedules.

- Simulation & training: High-fidelity simulators support crane operators—from apprenticeships to advanced refreshers—before they touch a live construction site. (Think union halls, OEM simulators, and West Coast training providers.)

Challenges When Introducing a Crane on a Project

Bringing a crane onto a site isn’t just about the equipment; it’s a mini-project of its own:

- Engineering & permits: Crane’s base design (or tie-in design) needs stamped calcs. Road closures, air rights, and neighbourhood notifications are common for tight urban jobs.

- Logistics & set-up: Staging flatbed trucks, sequencing boom sections and mast sections, and arranging assist cranes.

- Wind & weather: High winds force shutdowns; operators follow OEM wind charts and site rules.

- Capacity & reach planning: Pick radius, length of the boom, end of the boom deflection, and lifting capacity must match the type of crane and load plan.

- Maintenance & inspection: Regular inspection routines (rope, sheaves, brakes, bolts, hydraulic fluid, hydraulic cylinders) catch wear before it becomes major issues.

- Training & culture: Crane safety depends on a trained team—operators, riggers, signallers—with a shared commitment to safety measures.

- Budget & schedule: Mobilization/demobilization, rental rates, and wind downtime affect cost and program.

Best Practices: Safety Measures and Smooth Day-to-Day Operations

- Plan the lifts. Use engineered lift plans for heavy or complex picks; confirm maximum amount of weight and radius limits from the LMI.

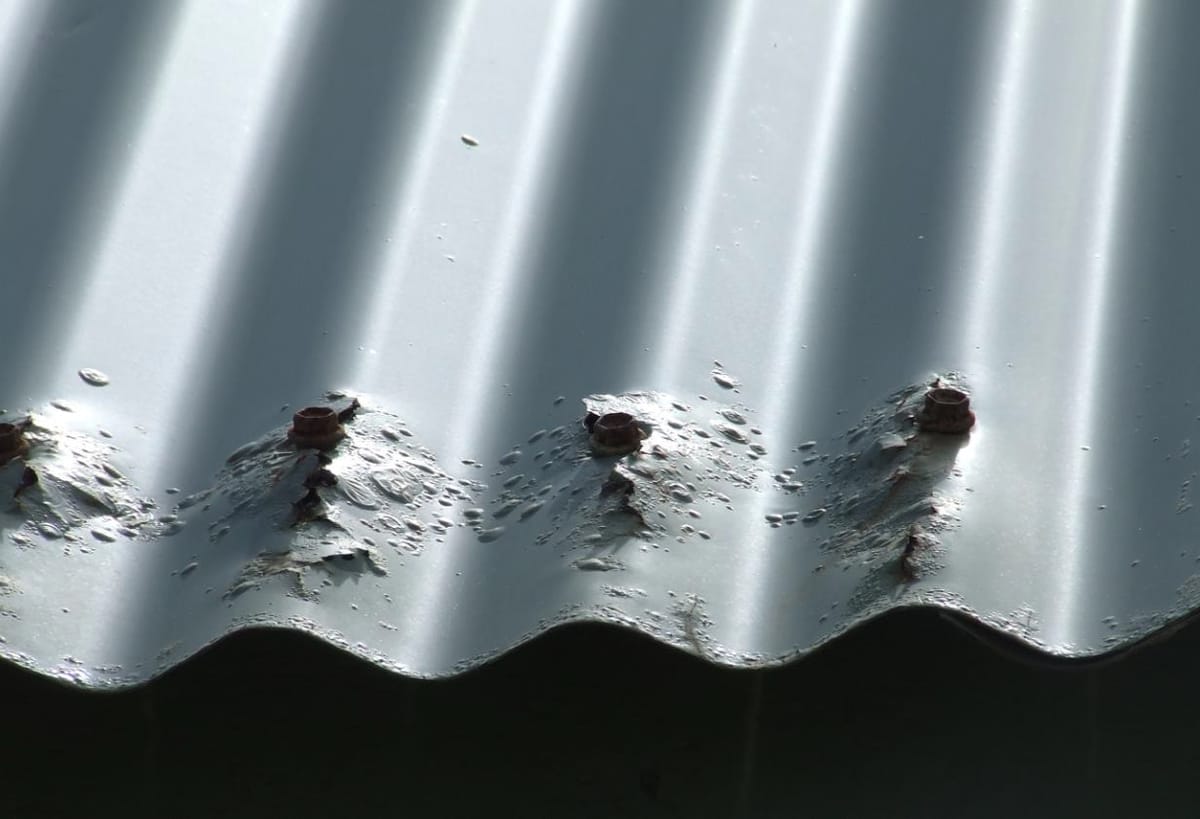

- Inspect relentlessly. Regular inspection of wire rope, sheaves, hooks (including the safety latch), pins, hydraulic mechanism, and structural joints.

- Monitor wind. Enforce wind speed limits; secure the jib per OEM guidance when storms roll through.

- Communicate. Clear hand signals, radios, and consistent terminology between crane operators and riggers at the construction site.

- Keep loads stable. Use tag lines, control swing during the crane’s movements, and avoid side loading.

- Mind the foundation. Watch for settlement around the concrete foundation or uneven outrigger pads on truck-mounted cranes.

- Stay within charts. Respect capacity charts for every configuration—telescopic boom at full extension isn’t the same as mid-stick.

- Document everything. Daily logs, maintenance records, and incident near-miss notes support continuous improvement.

A Quick Word on Fasteners (Because Bolts Hold Your Crane Together)

Cranes rely on bolted connections—especially where mast sections join, where slewing rings mount at the top of the mast, and at crane’s base connections to the concrete foundation. Using the correct grade bolts, proper torque, and re-torque intervals is essential to avoid loosening under vibration.

Think of it this way: if the fasteners slip, the crane tower can go out of alignment, causing uneven wear on the slewing unit and affecting precise crane movements. Good crews treat fasteners as a safety system, not just hardware.

Who Picks the Right Type of Crane—and How?

Typically, the general contractor or construction companies work with a specialty crane company and the project engineer.

Together they’ll evaluate:

- Load cases (unit weight, rigging gear, crane hook clearances)

- Reach (length of the boom, radius, end of the boom placement)

- Site constraints (adjacent buildings, work site obstructions)

- Ground conditions (concrete foundation vs. mats for mobile setups)

- Schedule (how long the crane stays up; need to climb to a higher level)

- Budget (rentals, crew time, street closures)

Are There Other Names for Cranes?

Yes—terminology shifts by market. You’ll see:

- Hammerhead cranes for standard horizontal-jib tower cranes (often the same as t-tower cranes in specs).

- City cranes for compact, smaller cranes suited to tight urban sites.

- All-terrain cranes within mobile crane families (roadable but strong off-road).

- Self-erecting tower cranes for low- to mid-rise work with faster setup.

Knowing the aliases helps when you’re comparing quotes and reading spec sheets from different regions.

The Big Picture—Simple Machines, Sophisticated Control

Cranes blend basic principles of simple machines with advanced control systems to move heavy loads safely.

From crane parts like wire rope, pulley systems, hydraulic cylinders, and electric motors, to software like load moment indicators and anti-collision tech, they make modern building possible.

The key to success is picking the right type of crane, planning the work, respecting weather limits like high winds, and sticking to a culture of safe operations and regular inspection.

FAQs- Frequently Asked Questions

1) What’s the difference between a tower crane and a mobile crane?

A tower crane is anchored to a concrete foundation and built from mast sections to reach great heights with long radius; a mobile crane (truck-mounted cranes, telescopic boom) drives to site, sets outriggers, and is great for short-term picks and fast mobilization.

2) How do load moment indicators help with crane safety?

Load moment indicators compare radius, length of the boom, and crane’s load to capacity charts in real time, warning the operator before you exceed the maximum amount of weight. They’re central to safe operations and efficient crane operations.

3) When do wind limits stop a lift?

Manufacturers set wind speed limits by configuration. Operators suspend lifting in high winds and secure the jib (weather-vane or luff to a safe angle) to protect the top of the crane and the structure.

4) How does a crane climb as the building gets taller?

With a climbing frame and hydraulic jacks. In the internal climbing method, the crane jacks up inside the core and inserts new tower sections; with the external climbing method, it’s tied to the building exterior and raised as floors advance to the next higher level.

5) What are the main safety features on the hook and hoist?

A safety latch on the crane hook, limit switches, overload protection, and emergency stops. Good regular inspection of wire rope, sheaves, and brakes catches wear before it becomes major issues.

6) Who designs the crane’s base?

A qualified engineer designs the concrete foundation or tie-in, considering the weight of the crane, overturning forces, and site conditions. The OEM and crane company provide reaction loads and crane components data.

7) Are there digital or tech tools to improve operations?

Yes—control system diagnostics, telematics, anti-collision, load moment indicators, and operator simulators. These boost precise crane movements, uptime, and training outcomes.

8) How do truck deliveries fit into crane planning?

Sequence flatbed trucks for boom sections, mast sections, and counterweights; schedule assist cranes; and plan laydown to keep the work site moving.

9) Can a crawler crane replace a tower crane?

Sometimes. A crawler crane shines for heavy picks at lower heights or big infrastructure sites. For dense urban high-rise buildings, a tower crane is typically the better fit.

10) What’s at the back of the crane?

The counter jib and counterweights (concrete blocks). Balancing the working arm keeps the system stable during crane’s movements.

Further Reading

Member discussion