Ever wondered what the difference is between galvanising and zincalume? Or why some metals have a shiny silver coating while others are dull grey? If you’re building or renovating a home, understanding metal coatings is important to ensure you get the right materials for the job.

In this quick explainer, we’ll run through the common protective coatings used on metals in residential construction so you know exactly what you’re getting.

Galvanising: The Original Protective Coating

Galvanising is a simple process where steel is coated in zinc to prevent rusting. The steel is dipped in molten zinc, which bonds to the surface to form a protective coating. For residential construction, galvanised steel is commonly used for:

- Roofing sheets and flashings. The zinc coating prevents rust and corrosion for decades, keeping your roof watertight.

- Gutters and downpipes. Galvanised steel is durable and weather-resistant, ideal for channelling water away from your home.

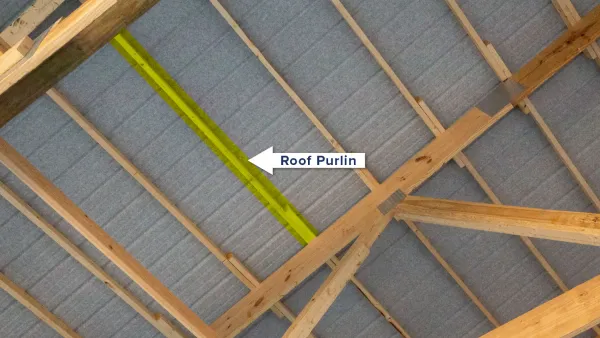

- Framing and structural building elements. Galvanised steel provides structural strength without the worry of rust.

The zinc barrier prevents oxygen and water from reaching the steel beneath. If the coating is scratched or damaged, the zinc will continue to protect the exposed steel by corroding instead, in a process called ‘galvanic protection’.

The thickness of the zinc coating is measured by its ‘zinc weight’ - how many grammes of zinc are applied per square metre. For residential purposes, a zinc weight of Z600 or higher is suitable, giving decades of protection.

While galvanising has been used for over 150 years, modern techniques now produce a more even coating that looks less ‘patchy’. The end result is an affordable, durable and low-maintenance solution to keep the structural steel elements of your home protected from the elements.

Galvanising may be an ‘oldie’ but it’s still a goodie. This time-tested technique has stood the test of time for good reason. For residential construction, it’s hard to beat galvanised steel for rust-free performance at a budget-friendly price.

Zincalume: Next Generation Protection

Zincalume steel is the next generation of protective metal coatings. It improves upon traditional galvanised steel by using a zinc-aluminium alloy coating instead of pure zinc.

Zincalume steel, invented by BlueScope Steel, is ideal for residential and commercial roofing and wall cladding. The zinc-aluminium alloy coating provides superior corrosion resistance to galvanised steel. It protects the base metal by creating a strong barrier against water and oxygen.

The alloy coating also has 'self-healing' properties. When the coating is scratched or damaged, the zinc and aluminium in the alloy react with moisture and oxygen in the air to form a protective layer, preventing further corrosion. This means Zincalume steel can last up to four times longer than galvanised steel.

Zincalume steel is also highly resistant to 'white rust' (a white, powdery zinc corrosion product). The aluminium in the alloy inhibits the formation of white rust, even in humid, highly alkaline environments.

With its superior durability and corrosion protection, Zincalume steel is perfect for the harsh Australian climate. It requires little maintenance and can withstand exposure to heat, humidity, pollution, salt spray, and acid rain.

If you want a roofing and walling product that will stand the test of time, Zincalume steel is worth considering for your next home construction project. Strong, lightweight, and amazingly resilient, this next-gen coating provides lasting protection for all your metal components.

Passivated Zinc Coatings: Specialty Protection

Passivated zinc coatings provide specialty corrosion protection for residential construction. This coating is a thin, transparent layer applied over a zinc coating like galvanising. It creates a protective barrier, preventing oxygen and moisture from reaching the zinc.

The passivation process involves treating the zinc coating with a chromate solution, which reacts with the zinc to form a tough, adherent barrier layer. This results in a coating with the corrosion resistance of zinc that also has the durability and weathering performance of paint.

Passivated zinc coatings are often used for:

- Roofing and gutters. The coating protects zinc roofing and gutters from weathering and corrosion for up to 20 years.

- Structural steel. Steel frames, posts, and beams used in house construction can be protected for many years.

- Fasteners. Bolts, nuts, washers, brackets, and other hardware attached to zinc or steel. The coating prevents corrosion that leads to staining.

Compared to paint, passivated zinc coatings provide longer-lasting protection without the need for frequent touch-ups or re-coating. They are a cost-effective, low-maintenance option for residential applications where both corrosion resistance and an attractive appearance are important.

While not as widely used as galvanising, passivated zinc coatings deserve consideration for niche applications where their unique properties provide benefit. They represent an underutilised tool in the home builder’s rust-prevention toolkit.

Conclusion

As you can see, there are several options for protecting metal surfaces in and around your home. Whether you need to shield roofing, gutters or structural steel from corrosion, galvanising, zincalume or passivated zinc coatings have got you covered. They each have their pros and cons depending on factors like cost, durability and appearance. The key is choosing a coating suited to your specific needs and climate.