8 Different Types of Brick Masonry House Construction

Brick masonry is a popular choice for house construction due to its durability, aesthetics, and flexibility. But did you know there are eight different types of brick masonry that can be used? Each type has its own unique characteristics that make it suitable for different applications.

Introduction

When building a new home, the choice of construction materials plays a pivotal role in defining not only the aesthetic appeal of your residence but also its durability, energy efficiency, and overall sustainability. Among the myriad options available to prospective homeowners, brick masonry stands out for its timeless elegance, structural integrity, and versatile application for both interior and exterior walls.

Brick masonry, a construction technique that has stood the test of time, offers an array of choices, each with its unique characteristics, benefits, and considerations. From the traditional charm of solid brick walls to the innovative advantages of engineered brick masonry, the selection process can be both exciting and overwhelming. This guide aims to demystify the different types of bricks masonry house construction, helping you make an informed decision tailored to your specific needs, preferences, and budget.

As we look into brick masonry, we'll explore eight distinct types, including the natural beauty of sandstone bricks/block construction, and discuss their respective advantages, disadvantages, best use cases, and cost implications. Whether you're drawn to the classic appeal of burnt clay bricks or the environmental benefits of ash bricks, understanding the differences between these options will empower you to choose the best bricks for your new brick homes.

1. Solid Brick Masonry

Solid brick masonry, a hallmark of traditional construction, is renowned for its strength, durability, and aesthetic versatility. Predominantly made from burnt clay or concrete, solid bricks have been a staple in construction for centuries, offering unparalleled load-bearing capabilities and a natural resistance to fire and pests.

Advantages:

- Durability: Solid masonry walls are capable of withstanding the test of time, often lasting as long as the buildings they support.

- Load-Bearing Capacity: They provide significant structural strength, making them ideal for supporting heavy loads and contributing to the overall stability of the structure.

- Fire Resistance: The inherent fire-resistant properties of solid bricks add an extra layer of safety to homes.

Disadvantages:

- Cost: The quality and labour-intensive nature of solid brick construction make it one of the more expensive options.

- Energy Efficiency: Solid brick walls can have lower insulation properties, potentially leading to higher energy costs without proper insulation techniques.

Best Use Cases: Perfect for homeowners seeking the classic beauty and enduring quality of traditional masonry for their permanent residence or commercial buildings.

Indicative Costs: Expensive. The combination of high-quality materials and the labour required for construction places solid brick masonry at the higher end of the cost spectrum.

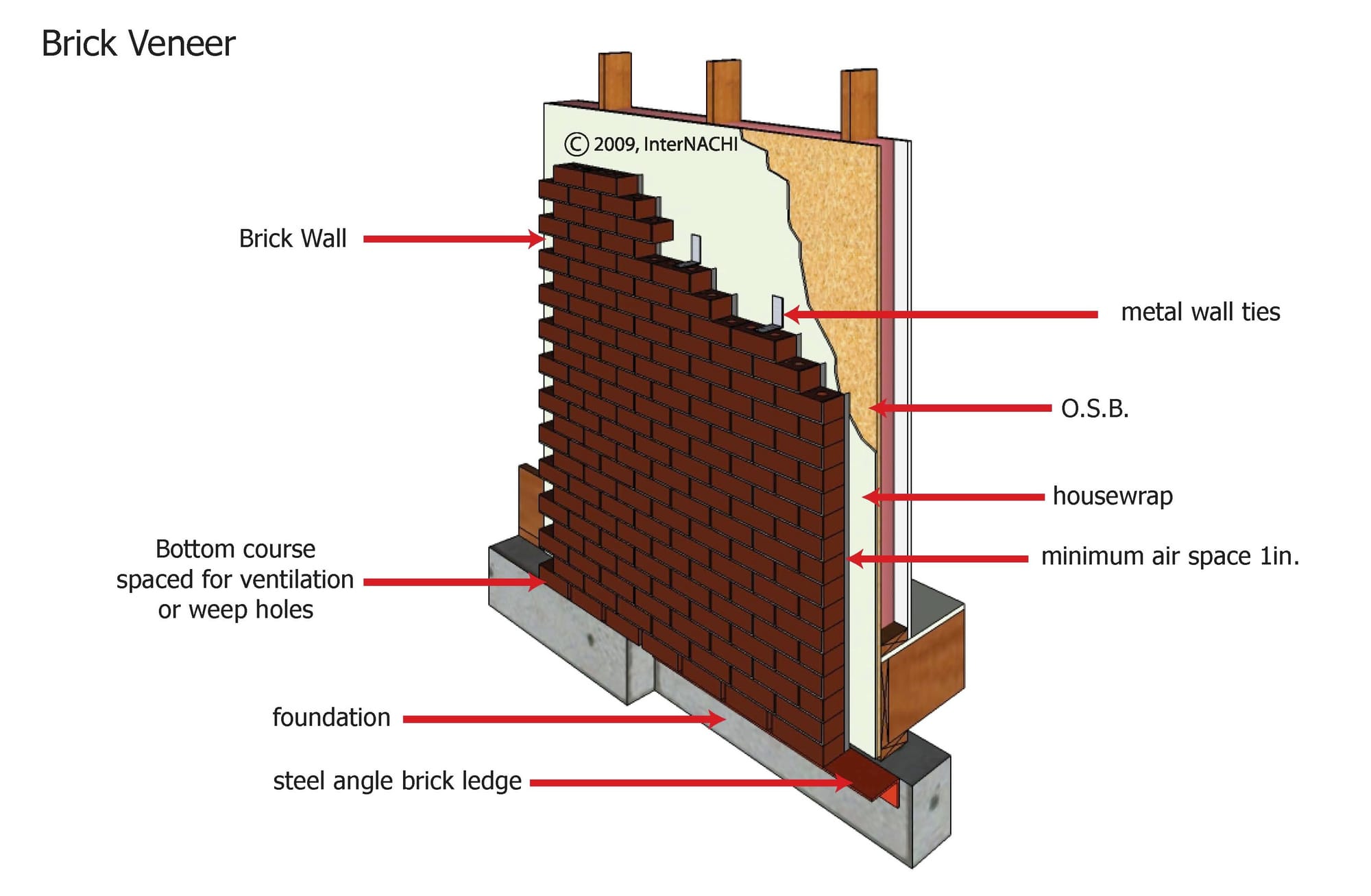

2. Brick Veneer Construction

Brick veneer construction offers the aesthetic appeal of brick but with a modern twist. Unlike solid brick masonry, brick veneer consists of a single layer outer wall, non-load bearing wall attached to the exterior of a structure built from another material, usually wood framing (wooden studs). This type of brick structure is a good choice when looking for a value for money structure with little maintenance while using only a single layer of brick. Brick veneer is the most common type of cladding system used in residential buildings in Australia.

Advantages:

- Thermal Insulation: The air gap between the brick veneer and the structural wall acts as an insulating layer, enhancing the building's energy efficiency. Brick veneer can be used where there is a required level of fire resistance.

- Cost-Effective: It provides the look of solid brick at a fraction of the cost and weight, making it a popular choice for budget-conscious homeowners.

- Flexibility in Design: Brick veneer allows for greater design flexibility and ease of repair compared to solid brick masonry.

Disadvantages:

- Structural Contribution: Brick veneer does not contribute to the load-bearing capacity of the building.

- Waterproofing Requirements: Proper installation and maintenance of waterproofing measures are crucial to prevent moisture ingress.

Best Use Cases: Ideal for homeowners desiring the aesthetic of brick without the structural requirements or cost associated with solid brick masonry.

Indicative Costs: Moderate. While less expensive than solid brick masonry, the cost of brick veneer construction includes the price of the bricks and the additional framing and insulation materials.

3. Cavity Walls

Cavity walls consist of two parallel walls with a gap (cavity) in between (tied together with metal ties), which can be filled with insulation material. This construction method significantly enhances thermal performance and moisture protection of the building.Cavity brick or cavity walls are what people are referring to when they refer to "solid brick houses"

Advantages:

- Enhanced Insulation: The cavity filled with insulating material greatly improves the building's heat retention and energy efficiency (ability to reduce transfer of high temperatures).

- Moisture Prevention: The cavity prevents moisture from penetrating the interior wall, protecting the building from dampness and related damage.

- Acoustic Insulation: Cavity walls also offer improved sound insulation, contributing to a quieter interior environment.

Disadvantages:

- Complex Construction: Building cavity walls is more complex and time-consuming than constructing solid or veneer brick walls.

- Higher Initial Cost: The improved benefits of cavity walls come at a higher initial investment due to the complexity of construction, labour costs and materials used.

Best Use Cases: Highly recommended for new constructions in climates with significant temperature variations, aiming for high energy efficiency and moisture protection.

Indicative Costs: Higher initial costs but potentially lower long-term expenses due to energy savings. The investment in cavity walls can be offset by the reduction in heating and cooling costs over time.

4. Concrete Blocks

Concrete block and concrete bricks masonry (solid masonry wall) is a versatile and cost-effective alternative to traditional brick construction. These blocks are larger than standard bricks, making them a popular choice for foundations and structural walls. A structural engineer loves to specify core-filled block walls for tight access becuase this type of masonry work is fast, simple to install and to reinforce and ready to receive applied waterproofing or finish coatings. This type of wall is less expensive than using pre-cast walling system although more time consuming to install than pre-cast.

Advantages:

- Cost-Effectiveness: The larger size and ease of laying concrete blocks make them a more economical choice for large construction projects.

- Structural Strength: Concrete blocks offer significant load-bearing capacity, suitable for foundations and structural walls.

- Speed of Construction: The larger size of concrete blocks means fewer units are required to cover the same area, speeding up the construction process.

Disadvantages:

- Aesthetic Limitations: Concrete blocks typically lack the traditional aesthetic appeal of bricks and may require additional finishing.

- Insulation Properties: While solid concrete blocks provide good thermal mass, they may not offer the same level of insulation as other construction methods without additional materials.

Best Use Cases: Ideal for commercial buildings, foundations, and structural elements where cost and construction speed are prioritized over aesthetic considerations.

Indicative Costs: Less expensive than solid brick masonry, concrete blocks offer a cost-efficient solution for large-scale construction projects.

5. Ash Bricks and Fly Ash Brick Masonry

Ash bricks, particularly fly ash bricks, are made from industrial waste products, combining fly ash, sand, and cement. They present an eco-friendly alternative to traditional bricks.

Advantages:

- Environmental Sustainability: Utilizing fly ash raw material, a by-product of coal combustion, reduces landfill waste and the environmental footprint of construction.

- Energy Efficiency: Ash bricks provide good insulation properties, contributing to more energy-efficient buildings.

- Cost Savings: The use of waste materials in manufacturing can make ash bricks a more affordable option.

Disadvantages:

- Regional Availability: The availability of high-quality fly ash bricks can vary by region, depending on local industrial activity.

- Consistency in Quality: There can be variability in the quality of ash bricks, affecting the uniformity and finish of the construction.

Best Use Cases: Suitable for eco-conscious construction projects, interior walls, and non-load bearing structures where sustainability and energy efficiency are key considerations.

Indicative Costs: Comparable to traditional bricks, with potential cost savings in markets where fly ash is readily available.

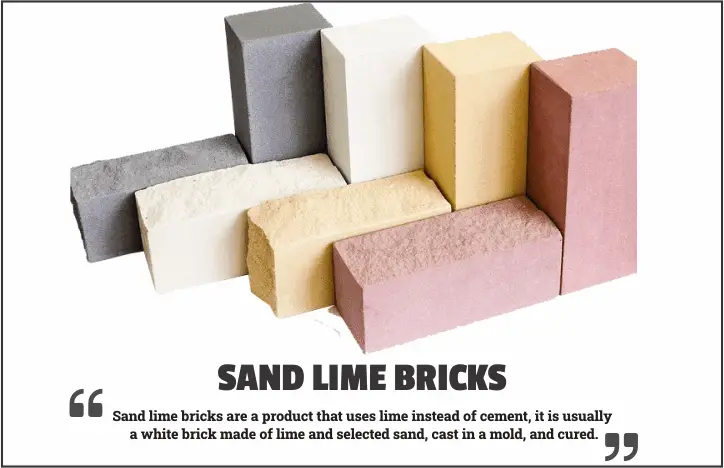

6. Sand Lime Bricks

Sand lime bricks are manufactured through a chemical reaction between sand, lime, and water. This method produces bricks with a smooth finish and a uniform color, making them a popular choice for both structural and aesthetic purposes.

Advantages:

- Aesthetic Appeal: Offers a smoother finish and more uniform color compared to traditional burnt clay bricks, enhancing the visual appeal of structures.

- Strength and Durability: These bricks provide good load-bearing capacity and are less prone to cracking compared to traditional bricks.

- Precision in Construction: Due to their uniform size and shape, sand lime bricks allow for more precise construction and tighter joints.

Disadvantages:

- Higher Cost: The manufacturing process of sand lime bricks is more complex, leading to higher costs than some other types of bricks.

- Limited Insulation: Similar to other masonry materials, they may require additional insulation to meet modern energy efficiency standards.

Best Use Cases: Ideal for facade work, load-bearing walls that require a smooth finish without additional plastering, and architectural details where precision and aesthetics are important.

Indicative Costs: More expensive than common bricks due to the specialized manufacturing process, but valued for specific applications where aesthetics and precision are paramount.

7. Engineered Brick Masonry

Engineered bricks are designed to exceed the performance of traditional bricks, offering enhanced strength, lower porosity, and greater durability against environmental stresses. They include types like calcium silicate bricks and high-strength engineering bricks.

Advantages:

- High Compressive Strength: Suitable for use in foundations, retaining walls, and other applications where strength is critical.

- Low Porosity: Offers excellent resistance to moisture and frost, protecting the structure from weather-related damage.

- Durability: Engineered to withstand harsh environmental conditions, making them ideal for use in exposed or high-traffic areas.

Disadvantages:

- Cost: Engineered bricks tend to be more expensive due to their enhanced properties and manufacturing processes.

- Availability: May be less readily available than traditional brick types, requiring special order or sourcing from specific manufacturers.

Best Use Cases: Best suited for projects requiring exceptional strength and durability, such as foundations, commercial buildings, and areas with severe weather exposure.

Indicative Costs: Among the more expensive options, reflecting their advanced engineering and performance characteristics. However, their durability and low maintenance requirements can offset the initial investment over time.

8. Sandstone Bricks/Block Construction

Sandstone bricks or blocks offer a unique and natural aesthetic, with each piece showcasing distinctive patterns and colors. This type of construction combines the timeless beauty of natural stone with the structural capabilities of masonry.

Advantages:

- Natural Beauty: Sandstone provides a warm, organic look with a range of natural colors and textures that cannot be replicated with manufactured products.

- Durability: When properly maintained, sandstone construction can withstand decades of exposure to the elements.

- Insulating Properties: Sandstone has natural insulating properties, making it an energy-efficient choice for building materials.

Disadvantages:

- Cost: Quarrying and processing sandstone can be more expensive than producing traditional bricks, making this option pricier.

- Maintenance: Sandstone is porous, requiring sealing to prevent moisture absorption and potential weathering or erosion over time.

Best Use Cases: Ideal for high-end residential and commercial buildings, landscaping features, and accent walls where the unique appearance of natural stone is desired.

Indicative Costs: Sandstone construction is generally more expensive due to the material's natural origin and the labour involved in quarrying and shaping the stones. However, its unique aesthetic and durability can add significant value to a property.

Conclusion

Choosing the right type of brick masonry for your home construction is a crucial decision that impacts not just the aesthetic of your home but also its durability, energy efficiency, and long-term maintenance requirements. From the traditional charm of solid brick masonry to the innovative benefits of engineered bricks and the natural beauty of sandstone, the options are diverse, each offering unique advantages and considerations.

As you embark on your home-building journey, carefully weigh the pros and cons of each type of brick masonry discussed here, considering your specific needs, environmental factors, and budget constraints. By doing so, you'll ensure that your new home not only looks beautiful but also stands the test of time, providing comfort and security for years to come.

Frequently Asked Questions and Answers

- What are the main factors to consider when choosing a type of brick for my home?

Choosing the right type of brick for your home involves considering several key factors, including:

- Aesthetic Preferences: The look and feel you desire for your home, as different bricks offer varying colors, textures, and finishes.

- Structural Requirements: Whether the brick will be used for load-bearing walls, façades, or decorative elements, affecting the choice between solid, veneer, and engineered bricks.

- Climate and Exposure: The local climate and potential exposure to elements can dictate the need for bricks with higher durability, water resistance, or insulating properties.

- Budget: The cost of materials and installation for each type of brick masonry can vary significantly, impacting the overall budget for your construction project.

- Maintenance: Consideration of the long-term maintenance required to keep the brickwork in good condition over time.

- How do the costs of different brick masonry types compare in the long run?

In the long run, the cost-effectiveness of a brick masonry type is influenced by its durability, maintenance requirements, and energy efficiency. For instance:

- Solid Brick Masonry: While initially more expensive, its durability and low maintenance can make it cost-effective over time.

- Brick Veneer and Cavity Walls: These may offer savings on energy bills due to better insulation, offsetting the initial investment.

- Concrete Blocks and Ash Bricks: Often less expensive upfront, these materials can be cost-effective for large projects or where high insulation values are not critical.

- Engineered and Sandstone Bricks: Though more costly initially, their superior durability and unique aesthetic may add value to the property, justifying the investment.

- Can I use different types of brick masonry for interior and exterior walls?

Yes, different types of brick masonry can be used for both interior and exterior walls, depending on the design and structural requirements of the project. For example:

- Interior Walls: Non-load bearing walls can utilize lighter materials like ash bricks or brick veneer for aesthetic purposes, while solid or engineered bricks may be chosen for structural or feature walls.

- Exterior Walls: Durability and insulation are key considerations, with solid bricks, cavity walls, and sandstone blocks being popular choices for their strength and weather resistance.

- What maintenance is required for brick masonry homes?

Maintenance requirements vary by the type of brick masonry:

- Solid Brick and Concrete Blocks: These generally require minimal maintenance, such as occasional cleaning and checking for mortar joint erosion.

- Brick Veneer and Cavity Walls: It's important to ensure weep holes remain unblocked and that any signs of moisture ingress are addressed promptly.

- Sandstone and Engineered Bricks: May require sealing or specific treatments to maintain their appearance and resistance to weathering.

- How do I ensure my brick masonry choice is environmentally friendly?

To choose environmentally friendly brick masonry:

- Opt for Recycled or Sustainable Materials: Consider bricks made from recycled materials or sustainable sources, such as fly ash bricks.

- Energy Efficiency: Select construction methods that enhance insulation and reduce energy consumption, like cavity walls.

- Durability and Longevity: Choosing durable materials that require less replacement and maintenance over time contributes to sustainability.

Discussion