Introduction

In a world where efficiency and continuous improvement are paramount, the concept of Kaizen has emerged as a transformative philosophy. Originating from post-war Japan, Kaizen, meaning "change for better," has transcended its industrial origins to influence diverse sectors, including residential construction.

This blog post looks into the essence of Kaizen and explores its practical application in the context of residential construction and construction processes.

By embracing the principles of continuous improvement, stakeholders in the construction industry can achieve remarkable strides in efficiency, quality, and client satisfaction. In the following sections, we'll uncover the origins of Kaizen, its fundamental principles, and the dynamic ways it can revolutionise residential construction.

Understanding Kaizen: Origins and Principles

The journey of Kaizen began in the bustling factories of post-war Japan, a testament to the country's resilience and commitment to progress. The term "Kaizen," which translates to "change for the better," encapsulates a philosophy of continuous, incremental improvement. Unlike radical changes, Kaizen focuses on small, manageable enhancements that collectively lead to significant advancements over time.

Core Principles of Continuous Improvement

At its core, Kaizen is underpinned by a set of principles that guide its practice:

- Good Processes Bring Good Results: The emphasis is on refining processes, with the belief that improved processes lead to better outcomes.

- Go See for Yourself: It encourages firsthand observation to understand the real issues.

- Empower Everyone: Kaizen is not just for managers; it involves every employee, from top management to the front lines.

- Challenge the Status Quo: Continuous improvement means always looking for ways to do better.

- Incremental Improvements: Instead of major changes, small, continuous changes are more sustainable and effective.

These principles have steered numerous industries towards greater efficiency and productivity. In the following section, we'll delve into how these principles are particularly suited for the unique challenges of residential construction, offering a roadmap for enhanced performance and client satisfaction.

Kaizen in Residential Construction: The Need and Benefits

Residential construction, an industry often characterised by tight deadlines, budget constraints, and quality demands, faces a myriad of challenges. These challenges can lead to delays, cost overruns, and compromised quality. However, the application of Kaizen principles offers a beacon of hope, transforming these challenges into opportunities for growth and improvement.

Addressing Challenges with Kaizen

The implementation of Kaizen in residential construction addresses key industry challenges:

- Reducing Waste: Kaizen helps in identifying and eliminating waste in processes, whether it's in materials, time, or labor.

- Enhancing Quality: Continuous improvement focuses on quality at every step, reducing the likelihood of errors and defects.

- Improving Efficiency: Streamlining processes leads to more efficient project completion, saving time and resources.

- Boosting Worker Morale: Involving workers in the improvement process increases engagement and job satisfaction.

Benefits of Kaizen in Residential Construction

The benefits of applying Kaizen in this sector are substantial:

- Cost Reduction: Efficient processes and reduced waste directly translate into cost savings.

- Increased Client Satisfaction: Enhanced quality and timely project completion lead to happier clients.

- Flexibility and Adaptability: Continuous improvement fosters a culture of adaptability, crucial in an industry where change is constant.

- Sustainable Practices: Kaizen encourages environmentally sustainable practices through efficient use of resources.

In the next section, we will explore the key strategies for applying Kaizen in construction processes, providing a practical guide for industry professionals seeking to adopt this transformative approach.

Key Strategies of Applying Kaizen in Construction Processes

Implementing Kaizen in residential construction involves a strategic approach that focuses on continuous improvement at every level. The following are key strategies for effectively integrating Kaizen into construction processes:

1. Establishing a Culture of Continuous Improvement

- Leadership Commitment: Success starts at the top. Leaders must demonstrate a commitment to continuous improvement and support initiatives.

- Employee Involvement: Engage workers at all levels in identifying areas for improvement. This inclusive approach ensures a diverse range of perspectives and solutions.

2. Process Analysis and Streamlining

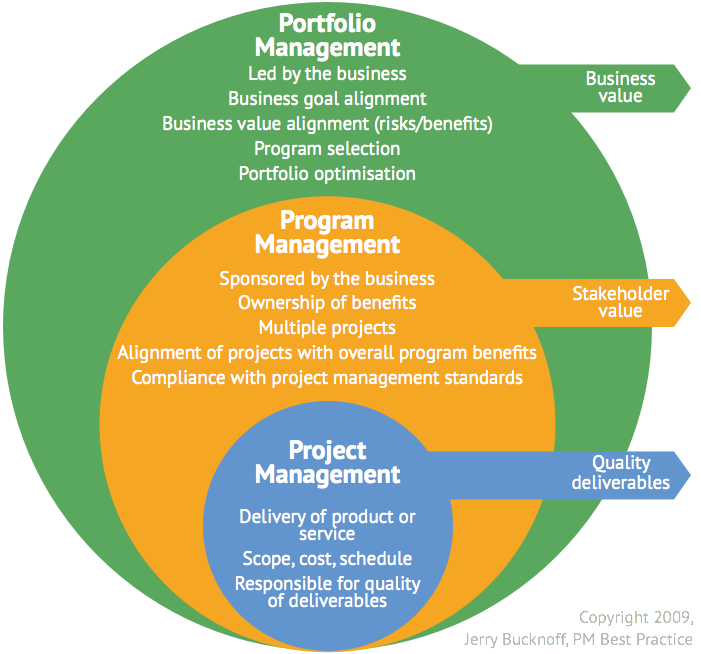

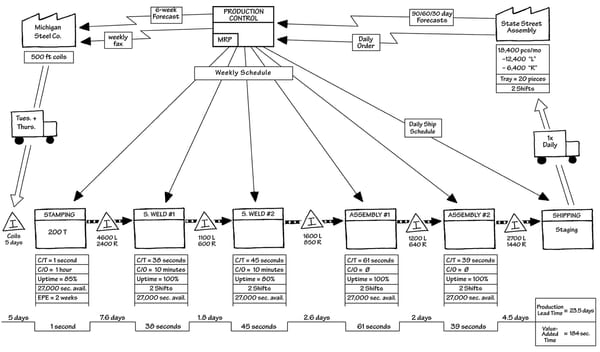

- Value Stream Mapping: Identify each step in the construction process and analyze it for value addition. This helps in pinpointing non-value-adding activities (waste).

- Standardisation of Best Practices: Once effective methods are identified, standardise them to ensure consistency across projects.

3. Implementing the 5S Methodology

- Sort, Set in Order, Shine, Standardise, and Sustain: These steps help organise the workplace, making it efficient and safe.

4. Continuous Learning and Adaptation

- Regular Training and Workshops: Keep the team updated with the latest construction techniques and technologies.

- Feedback Loops: Encourage feedback from employees and clients to continually adapt and improve processes.

5. Real-World Examples and Case Studies

Illustrating the application of these strategies, several residential construction companies have seen remarkable improvements:

- Case Study 1: A company implemented 5S and saw a 20% reduction in tool retrieval time.

- Case Study 2: Another firm focused on process streamlining, resulting in a 15% decrease in project completion time.

By integrating these strategies, construction companies can create a dynamic environment where continuous improvement is not just a concept but a day-to-day reality. This approach leads to increased efficiency, cost savings, and higher client satisfaction.

Tools and Techniques for Kaizen in Construction

To effectively implement Kaizen in the field of residential construction, several tools and techniques can be employed. These not only facilitate continuous improvement but also ensure that the improvements are sustainable and measurable.

1. PDCA Cycle (Plan-Do-Check-Act)

- Plan: Identify areas for improvement and develop a strategy.

- Do: Implement the plan on a small scale to test its effectiveness.

- Check: Evaluate the results and identify any gaps or issues.

- Act: Based on the evaluation, refine the plan and implement changes on a larger scale.

2. Root Cause Analysis

- Fishbone Diagram: A tool to identify and visualise the root causes of a problem, not just its symptoms. This helps in pinpointing specific areas for improvement.

3. Visual Management

- Kanban Boards: Visual tools to track progress and manage workflow. This helps teams stay organised and focused on current tasks.

- 5S Visual Cues: Use of labels, color coding, and signage to maintain organisation and efficiency in the workspace.

4. Continuous Feedback and Improvement Loops

- Regular Team Meetings: Encourage open discussion and sharing of ideas for improvement.

- Client Feedback Systems: Implement systems to gather and analyze client feedback, which can be a valuable source of insight for improvement.

5. Technology Integration

- Project Management Software: Tools that facilitate better planning, tracking, and collaboration.

- Building Information Modeling (BIM): Technology that allows for more efficient planning and visualisation of construction projects.

By leveraging these tools and techniques, residential construction companies can foster a Kaizen mindset, leading to enhanced efficiency, better resource management, and increased customer satisfaction. These methodologies not only streamline processes but also build a culture of constant learning and adaptation.

Overcoming Challenges: Kaizen in the Real World

While the implementation of Kaizen in residential construction offers numerous benefits, it's not without its challenges. Understanding and addressing these challenges is key to successfully adopting this philosophy.

Resistance to Change

- Challenge: One of the biggest hurdles is resistance to change from employees and management.

- Solution: Effective communication, education, and involving employees in the change process can help in easing this transition.

Consistency in Application

- Challenge: Maintaining consistency in applying Kaizen principles across different projects and teams.

- Solution: Regular training, workshops, and leadership by example are crucial in embedding a culture of continuous improvement.

Measuring Improvements

- Challenge: Quantifying the benefits and improvements can be difficult, especially in the short term.

- Solution: Set clear, measurable goals and use data-driven approaches to track progress. Celebrate small victories to keep the team motivated.

Integrating with Existing Processes

- Challenge: Integrating Kaizen with existing processes without causing disruptions.

- Solution: Start with small, incremental changes rather than overhauling processes entirely. This gradual approach is less disruptive and more manageable.

Keeping Up with Technological Advances

- Challenge: The construction industry is rapidly evolving, and keeping up with technological advances can be daunting.

- Solution: Foster a culture of continuous learning, and encourage employees to stay updated with the latest trends and technologies.

By acknowledging and strategically addressing these challenges, companies can effectively harness the power of Kaizen, turning potential obstacles into opportunities for further growth and development.

Conclusion

The philosophy of Kaizen, with its roots in post-war Japan, has shown its versatility and effectiveness in various industries, including residential construction. By adopting the principles of continuous improvement, companies in the construction sector can achieve significant advancements in efficiency, quality, and client satisfaction.

The journey of implementing Kaizen is not without challenges, but the potential rewards make it a compelling choice for those looking to innovate and improve. As the construction industry continues to evolve, embracing Kaizen can be a key differentiator, driving sustainable growth and competitive advantage.

Key Article Takeaways

- Kaizen's Core Principle: Continuous, incremental improvement is at the heart of Kaizen, leading to significant long-term benefits.

- Strategies for Implementation: Establishing a culture of improvement, process analysis, and employing tools like PDCA and 5S are key to integrating Kaizen.

- Overcoming Challenges: Addressing resistance to change, ensuring consistency, and keeping up with technology are essential for successful implementation.

- Benefits: Improved efficiency, reduced waste, enhanced quality, and increased client satisfaction are among the notable benefits of applying Kaizen in residential construction.

Frequently Asked Questions (FAQs)

Q: Can Kaizen be applied to small-scale residential construction projects?

A: Absolutely. Kaizen is scalable and can be applied to projects of any size, bringing improvements in efficiency and quality.

Q: How long does it take to see the results of implementing Kaizen?

A: While some improvements can be seen relatively quickly, Kaizen is about long-term, continuous improvement. The full benefits are often realized over a longer period.

Q: Is Kaizen applicable only to the construction phase, or can it be used in planning and design as well?

A: Kaizen can and should be applied throughout all phases of a construction project, including planning, design, and execution.

Q: How do you measure the success of Kaizen in construction?

A: Success can be measured through various metrics such as reduction in waste, time savings, cost efficiency, and client satisfaction scores.